Short Lead Time for Automated High Bay Warehouse - Vertical Spiral Conveyor Screw System – Ouman

Short Lead Time for Automated High Bay Warehouse - Vertical Spiral Conveyor Screw System – Ouman Detail:

Product Introduction

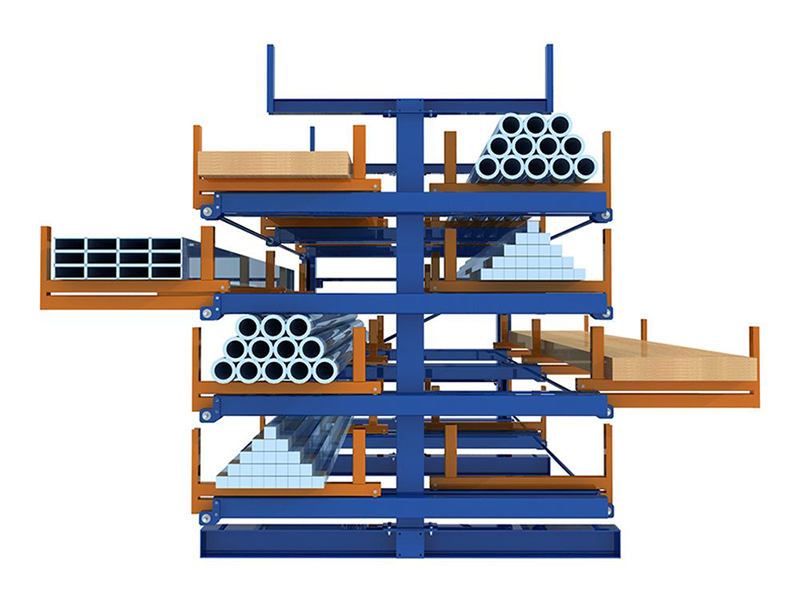

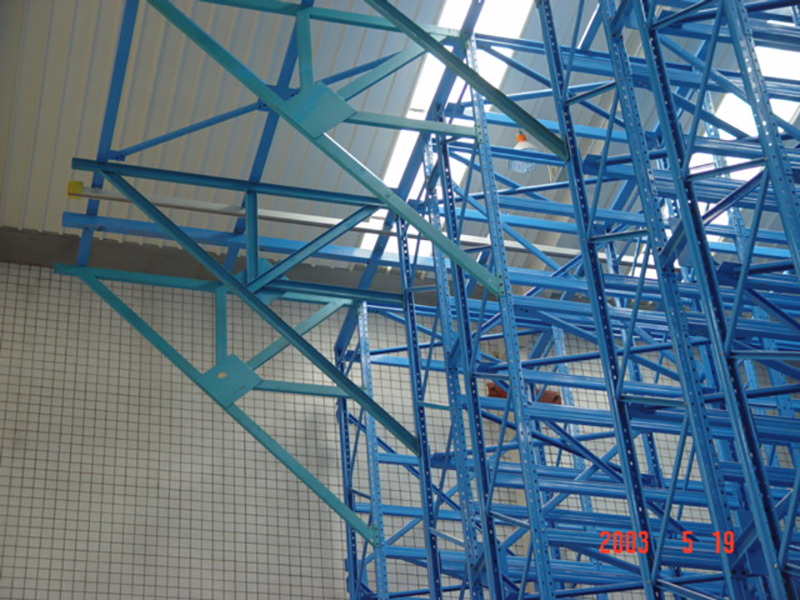

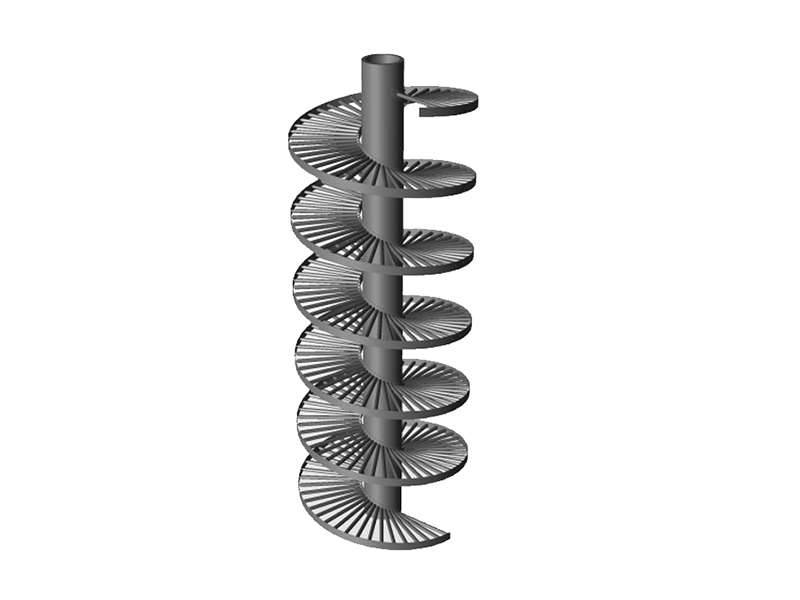

Spiral conveyors is a kind of automatic system for warehouse to deliver and transfer goods from racking system. It can be used for merging products from a multi-level pick module on to a single takeaway conveyor line. They can also be help accumulate product on the spiral to increase buffer time. Customizable to safely handle a variety product, we can help you implement the right cost-effective solution for your operations.

Features & Advantages

● Spiral conveyor system is easy to install

● Maximize the floor space with conveyor the goods vertically

● Compared with cargo lifts or elevators, it is much faster, and more reliable

● Provide the chance to load and unload the goods directly at different levels

● Different types of conveyor system( roller lines, belt conveyor system and etc) can be used together the vertical spiral system

Advantages of Automatic Spiral Conveyor System

What types of products can be used on the spiral conveyor system?

1.Suitable products: Bags, bundles, totes, trays, cans, bottles,containers, carton boxes and wrapped&unwrapped items

2.Suitable industries: food industry, beverage industry, newspaper industry, pet food & personal care industry and many others

Technical data of spiral conveyor system

|

Item Name |

Vertical Spiral Conveyor Screw System |

|

Main material |

Painting carbon steel and stainless steel |

|

Belt Material |

Chain plate,roller,plastic mesh,metal wire mesh |

|

Spiral width |

200mm, 300mm, 400mm, 600mm |

|

Total spiral length |

carbon steel bottom chain 60M,stainless steel bottom chain 48M |

|

Lifting height |

6m-20m |

|

Max load capacity |

carbon steel bottom chain<750kg,stainless steel bottom chain<600kg |

Brief Drawing of Spiral Conveyor System

Product detail pictures:

Related Product Guide:

Persisting in High good quality, Prompt Delivery, Aggressive Price, we've established long-term cooperation with shoppers from each overseas and domestically and get new and previous clients' high comments for Short Lead Time for Automated High Bay Warehouse - Vertical Spiral Conveyor Screw System – Ouman , The product will supply to all over the world, such as: Costa Rica, Jordan, South Africa, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.