Short Lead Time for Automated High Bay Warehouse - High density warehouse storage density pallet shuttle racking – Ouman

Short Lead Time for Automated High Bay Warehouse - High density warehouse storage density pallet shuttle racking – Ouman Detail:

Product Introduction

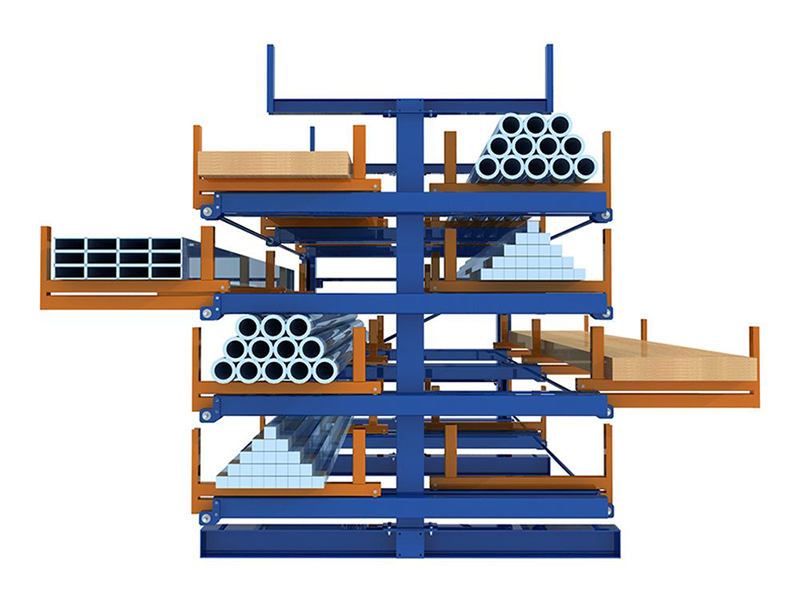

Radio shuttle racking is an advanced warehouse storage racking system. The most character is high storage density, convenient in inbound&outbound,high working efficiency. FIFO&FILO models improve the warehouse management. The whole radio shuttle racking system consists of the pallet shuttles, racking,forklifts and etc.

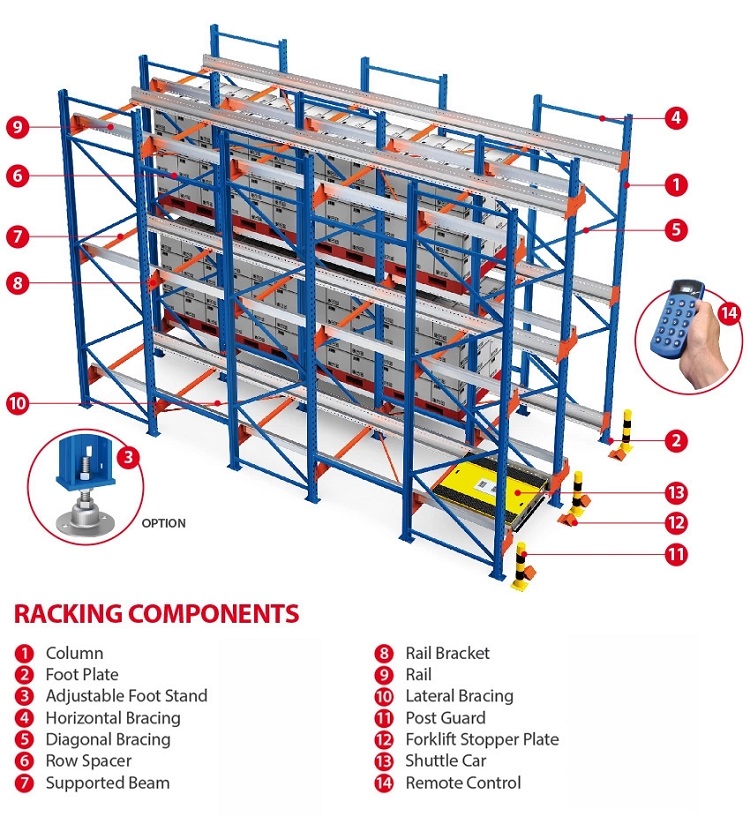

Main Structure of Radio shuttle racking

Radio shuttle racking is including the following items. Racking part, Radio shuttle cart, remote control, forklift and so.

Technical Data of Radio shuttle car

In the shuttle racking system, radio shuttle is a main part to make the shuttle racking works. We have our own radio shuttle cart for automatic radio shuttle racking.

|

Radio Shuttle Cart |

||

| Item No. | Item Name | Item Information |

|

Basic Data |

Size(mm) | L1040*W960*H180mm |

| Self Weight(kg) | 200kg | |

| Max Loading(kg) | 1500kg Max | |

| Operation Method | Manual&Automatic Operation | |

| Communicate Method | Wireless Communication | |

| Control Method | PLC,SIEMENS, | |

| Noisy Level | ≤60db | |

| Temperature | -40℃-40℃,-25℃-40℃,0℃-40℃ | |

|

Basic Data |

Running Speed | Empty loading:1m/s,Full loading:0.8m/s |

| Running Acceleration | ≤0.5m/S2 | |

| Running Motor | Brushless Servo Motor 48V/750W | |

| Lifting Height | 40mm | |

| Lifting Up Time | 4S | |

| Lifting Down Time | 4S | |

| Lifting Motor | Brushless Servo Motor 48V/750W | |

|

Positioning Method |

Running Location | Laser Positioning |

| Pallet Location | Laser Positioning | |

| Lifting Location | Proximity Switch Positioning | |

|

Safety Device |

Cargo Detecting | Background Suppression

Photoelectric |

| Anti-collision | Anti-collision Sensor | |

|

Remote Control |

Working Frequency | 433 MHZ Communication Distance≥100m |

| Communication Method | Two-way Communication Function | |

| Temperature | 0℃-50℃ | |

|

Battery Performance |

Power Supply Method | Lithium Iron Phosphate Battery |

| Electrical Press | 48V | |

| Battery Capacity | 30AH | |

| Charging Times | 1000times | |

| Charging Time | 2-3h | |

| Working Time | 6-8h | |

Advantages of Radio Shuttle Racking

1, High Storage Density and Improve the Warehouse Utilization.

Compared with the standard pallet racking, no need the more aisles for forklifts to work which can add more storage pallets in the warehouse.

2, High Safety Storage and Reduce the Loss.

Radio shuttle rack, forklift not drive in the racking aisles to load and unload the pallets from racking system. It helps to improve the storage operation safety.

3, High Working Efficiency and Reduce the Warehouse Cost.

Automatic radio shuttle racking system improve the warehouse operation working efficiency and because less workers works in the warehouse,reduce the warehouse invest cost.

Product detail pictures:

Related Product Guide:

As a way to ideal meet up with client's desires, all of our operations are strictly performed in line with our motto High high quality, Competitive Cost, Fast Service for Short Lead Time for Automated High Bay Warehouse - High density warehouse storage density pallet shuttle racking – Ouman , The product will supply to all over the world, such as: South Africa, Lahore, Miami, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be excellent business partner.