Revolutionize Your Warehouse with OUMAN RACKING ACR

Product Introduction

OUMAN RACKING's Multi-Layer Automated Case-Handling Robot (ACR) is a state-of-the-art solution designed to streamline warehouse operations. By leveraging advanced autonomous navigation technology, the ACR system implements a Goods-to-Person (G2P) automation model, significantly enhancing efficiency and accuracy.

Core Components

- ①ACR Robots: Precisely move and handle plastic totes or containers, ensuring efficient storage and retrieval.

- ②Intelligent Charging Stations: Automatically recharge the ACR robots, ensuring continuous operation.

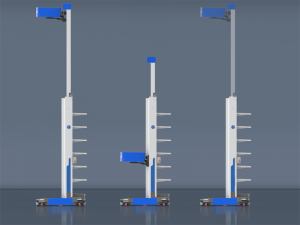

- ③Racking Shelving: Optimized for space utilization, supporting multi-layer storage to maximize vertical space.

- ④Multi-Function Workstations: Integrated with various operational functions for smooth and efficient goods handling.

- ⑤Warehouse Management System (WMS): Comprehensive management of inventory information, enabling intelligent scheduling and tracking.

- ⑥Warehouse Control System (WCS): Coordinates the operation of all equipment to ensure seamless workflow.

- ⑦Internet Hardware System: Connects all components to form a complete and integrated automation system.

Technical Specifications

| Parameter | Value |

| Lifting Height | Max Height 5200mm |

| Walking Speed | Avg: 1.5m/s, Max: 1.8m/s |

| Plastic Container Capacity | Normally 5pcs, up to 8+1 pcs |

| Plastic Container Size | 600x400x120-300mm, customizable |

| Container Load | 30kg-50kg |

| Navigation Methods | Inertial navigation + DM Code |

| Battery Life | More than 5.4 hours |

| Racking Type | Medium duty racking shelving |

| Aisle Width | 1110mm |

| Ground Flatness | ± 4mm/m² |

Key Advantages

1. High Working Efficiency:

The multi-layer ACR can carry up to 9 plastic containers at once, significantly improving picking efficiency and reducing operational time.

2. Flexible Payload Dimensions:

Supports both separate and mixed picking of plastic totes and carton boxes, accommodating a wide range of container sizes and types.

3.Strong Flexibility with Racking Solutions:

For new warehouses, we can design multi-row racking systems to optimize storage density. For existing warehouses, we offer renovation plans to integrate with the current racking infrastructure, ensuring high storage efficiency.

4.High Safety Standards:

Equipped with multiple safety features to ensure the robots operate in a safe environment, preventing accidents and ensuring smooth operations.

Additional Features

- Real-Time Monitoring: The WMS and WCS systems provide real-time data on inventory levels, robot status, and operational performance, allowing for proactive management and optimization.

- Scalability: The system is designed to be scalable, allowing for easy expansion as your business grows.

- User-Friendly Interface: The multi-function workstations feature intuitive interfaces, making it easy for operators to manage tasks efficiently.

- Energy Efficiency: The intelligent charging stations and energy-efficient design of the ACR robots reduce power consumption, contributing to lower operational costs.

Applications

-

- E-commerce: Ideal for handling high-volume orders with fast turnaround times.

- Retail: Enhances inventory management and order fulfillment processes.

- Manufacturing: Streamlines production line logistics and material handling.

- Logistics: Improves the efficiency of distribution centers and fulfillment centers