Quality Inspection for Automated Sheet Metal Storage Systems - Industrial warehouse storage radio shuttle pallet racking – Ouman

Quality Inspection for Automated Sheet Metal Storage Systems - Industrial warehouse storage radio shuttle pallet racking – Ouman Detail:

Product Introduction

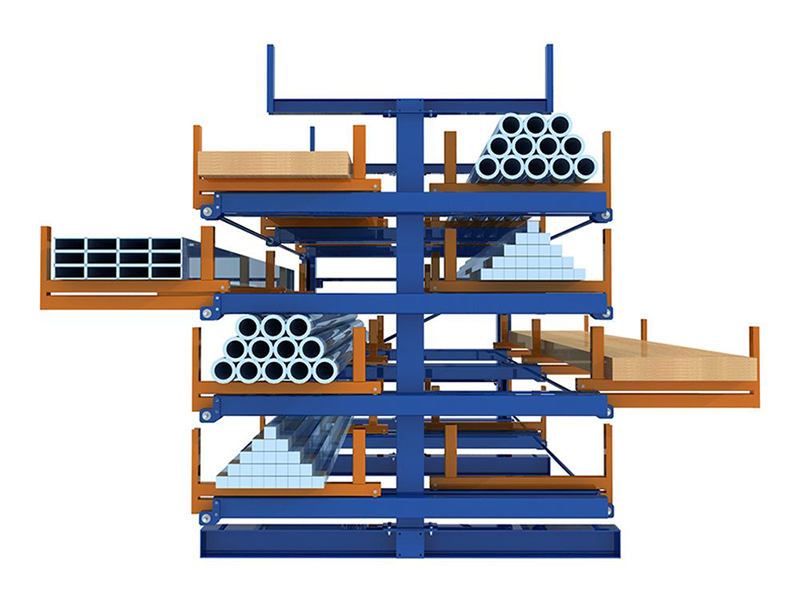

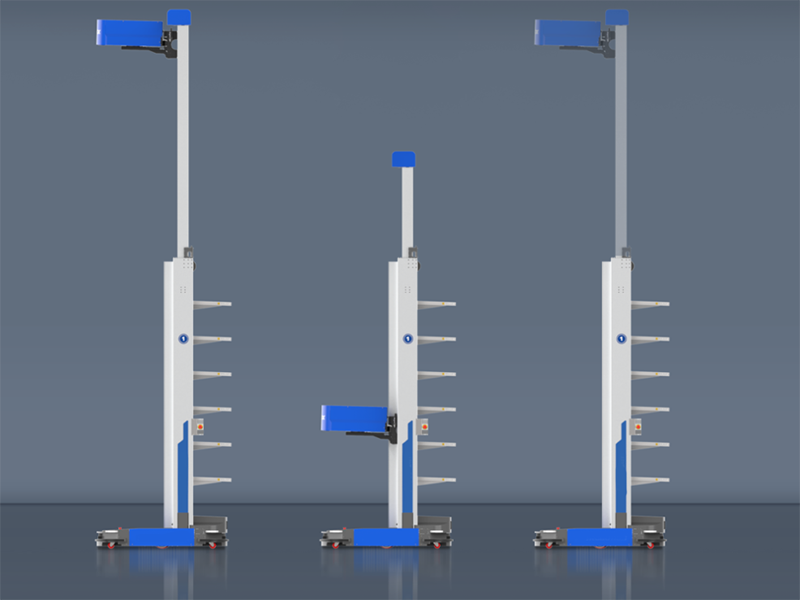

Radio shuttle pallet racking system is also called pallet shuttle racking shelving which is an semi-automated warehouse storage racking system for warehouse. Normally we use radio shuttle with forklift together to load and unload the goods. FIFO and FILO are both options for radio shuttle racking. Shuttles travel on the pallet rails and controlled by the wireless remote control to carry the pallets on the rails.

In the deep pallet locations of shuttle racking, shuttle travels to the pallets and lift up the pallets with cargo and carry the cargo to the unloading front ends. Then forklifts unload the pallets from the unload end. And forklifts also can help to switch the lanes.

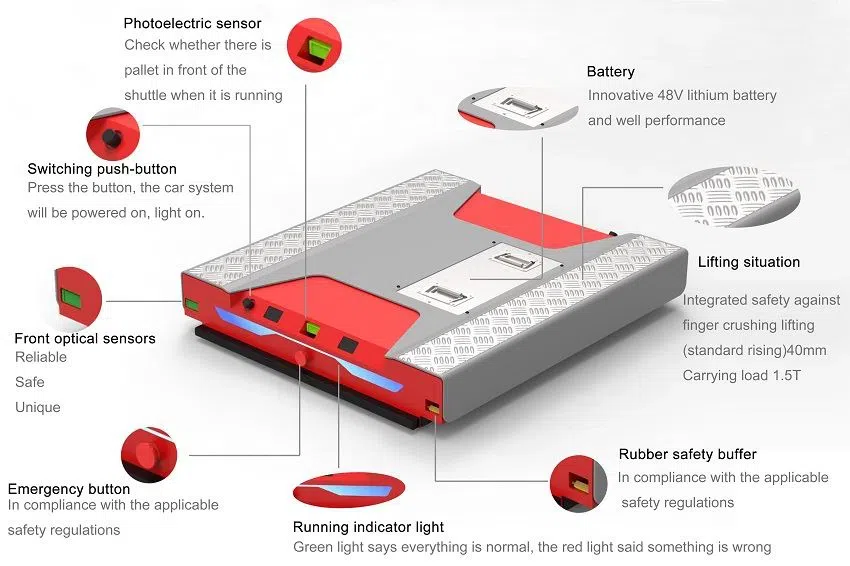

Main structure of radio shuttle cart

● Radio shuttle body

● Photoelectric Sensor

● Battery

● Lifting situation

● Rubber safety buffer

● Running indicator light

● Emergency button

● Front optical sensors

● Switching push button

Radio Shuttle Rack Features

● High density warehouse storage and offer high space utilization

● High working efficiency and reduce greatly the operation time

● Flexible operation with First in Last out and First in First out model

● High safety factors and reduce the forklifts’ collision to racking structure

● Low investment compared with other automatic racking system

What information required for radio shuttle racking system?

● Pallet size and load capacity

● Cargo weight

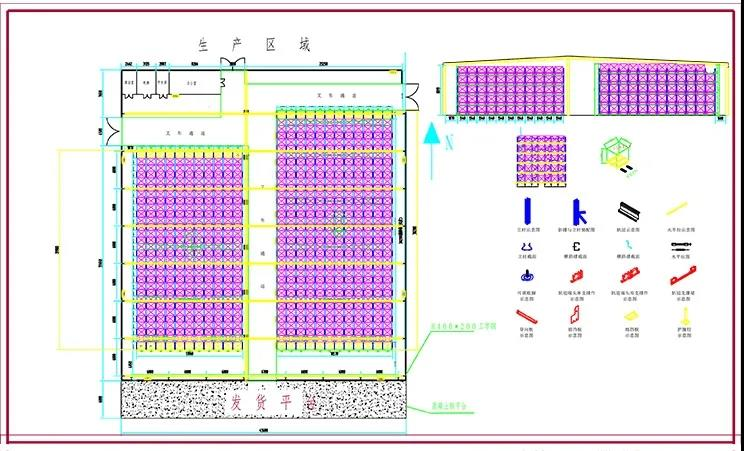

● Warehouse size/ warehouse drawing/area for shuttle racking

● Standard warehouse or cold warehouse

● Standard pallet shuttle, cold storage pallet shuttle or WIFI pallet shuttle

Radio shuttle rack application

● Suitable for the goods with large quantity but small variety Food industry, Beverage industry, Chemical industry, Tobacco industry and other industry

● Cold storage operation, reduce the low temperature working time and improve the working efficiency and working safety.

● Convenient management, high strict requirements for load and unload tragedy with FIFO & FILO.

● Improve warehouse storage capacity, shuttle racking has strong structure and can be designed with large pallet positions.

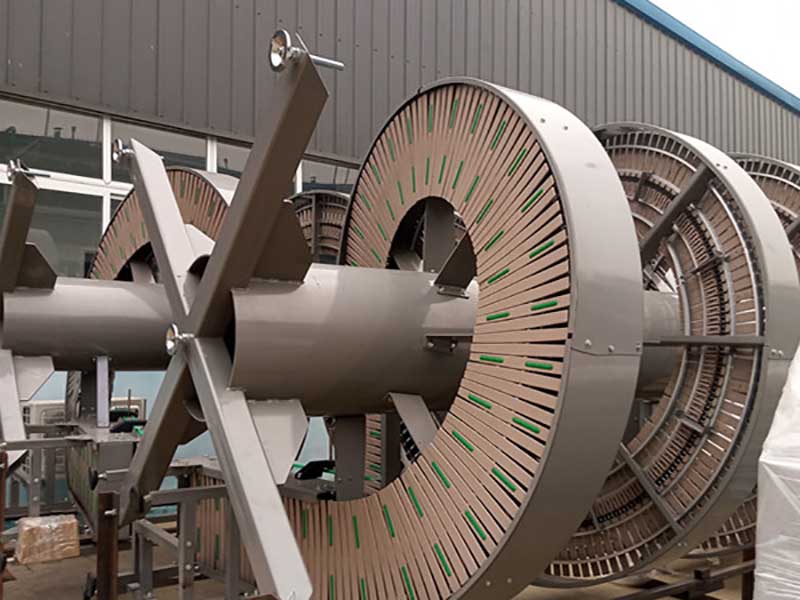

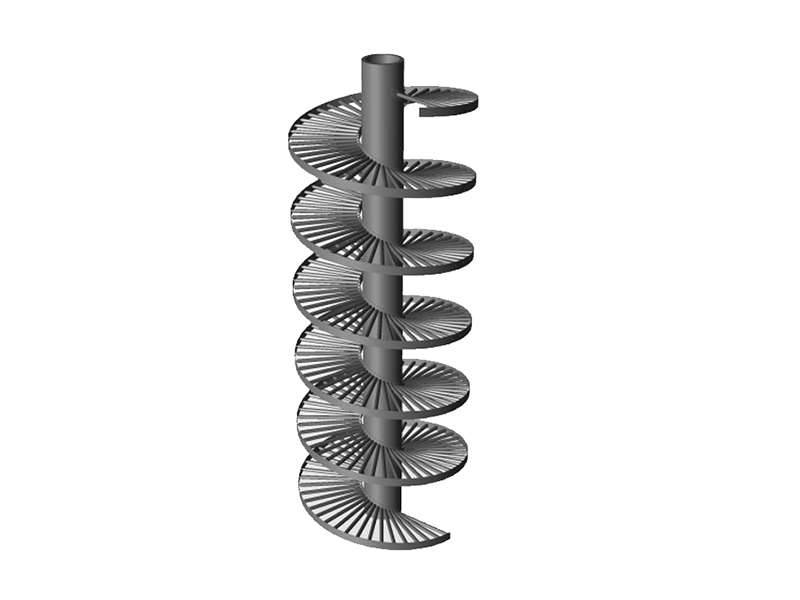

Product detail pictures:

Related Product Guide:

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Quality Inspection for Automated Sheet Metal Storage Systems - Industrial warehouse storage radio shuttle pallet racking – Ouman , The product will supply to all over the world, such as: Marseille, Latvia, South Korea, By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

It is really lucky to meet such a good supplier, this is our satisfied cooperation, I think we will work again!