PriceList for Automated Radio Shuttle - Industrial warehouse storage radio shuttle pallet racking – Ouman

PriceList for Automated Radio Shuttle - Industrial warehouse storage radio shuttle pallet racking – Ouman Detail:

Product Introduction

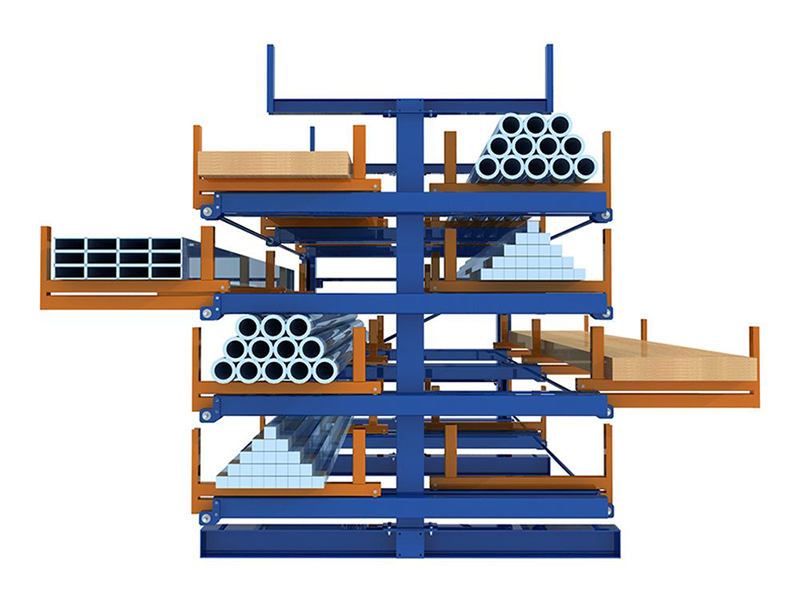

Radio shuttle pallet racking system is also called pallet shuttle racking shelving which is an semi-automated warehouse storage racking system for warehouse. Normally we use radio shuttle with forklift together to load and unload the goods. FIFO and FILO are both options for radio shuttle racking. Shuttles travel on the pallet rails and controlled by the wireless remote control to carry the pallets on the rails.

In the deep pallet locations of shuttle racking, shuttle travels to the pallets and lift up the pallets with cargo and carry the cargo to the unloading front ends. Then forklifts unload the pallets from the unload end. And forklifts also can help to switch the lanes.

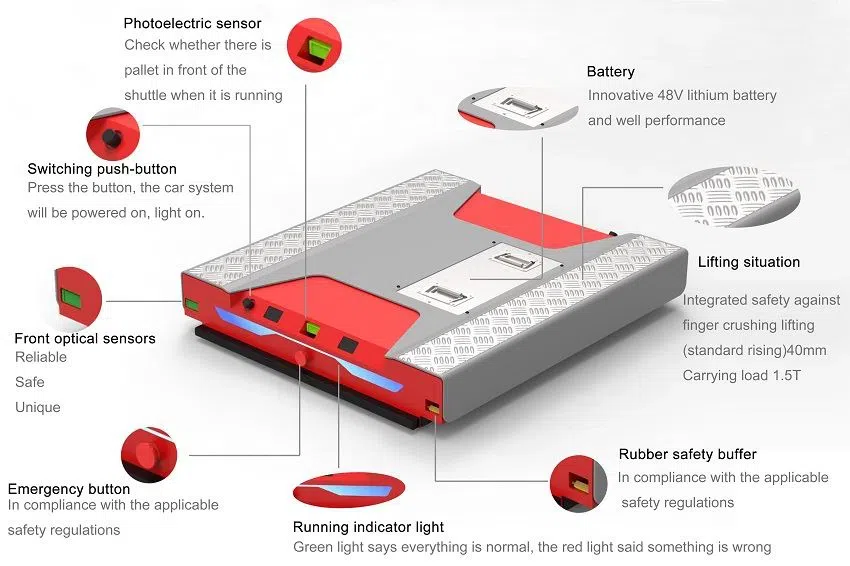

Main structure of radio shuttle cart

● Radio shuttle body

● Photoelectric Sensor

● Battery

● Lifting situation

● Rubber safety buffer

● Running indicator light

● Emergency button

● Front optical sensors

● Switching push button

Radio Shuttle Rack Features

● High density warehouse storage and offer high space utilization

● High working efficiency and reduce greatly the operation time

● Flexible operation with First in Last out and First in First out model

● High safety factors and reduce the forklifts’ collision to racking structure

● Low investment compared with other automatic racking system

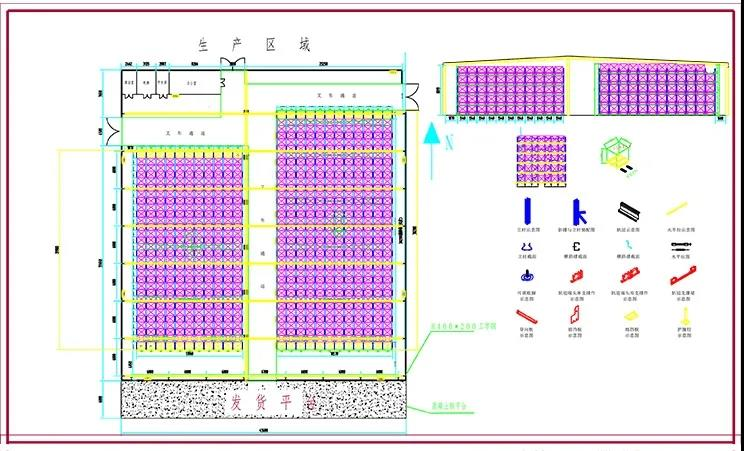

What information required for radio shuttle racking system?

● Pallet size and load capacity

● Cargo weight

● Warehouse size/ warehouse drawing/area for shuttle racking

● Standard warehouse or cold warehouse

● Standard pallet shuttle, cold storage pallet shuttle or WIFI pallet shuttle

Radio shuttle rack application

● Suitable for the goods with large quantity but small variety Food industry, Beverage industry, Chemical industry, Tobacco industry and other industry

● Cold storage operation, reduce the low temperature working time and improve the working efficiency and working safety.

● Convenient management, high strict requirements for load and unload tragedy with FIFO & FILO.

● Improve warehouse storage capacity, shuttle racking has strong structure and can be designed with large pallet positions.

Product detail pictures:

Related Product Guide:

The rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for PriceList for Automated Radio Shuttle - Industrial warehouse storage radio shuttle pallet racking – Ouman , The product will supply to all over the world, such as: Montreal, Finland, Bandung, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.