OEM manufacturer Conveyor Equipment - Mini load ASRS for Totes and Cartons – Ouman

OEM manufacturer Conveyor Equipment - Mini load ASRS for Totes and Cartons – Ouman Detail:

Product Introduction

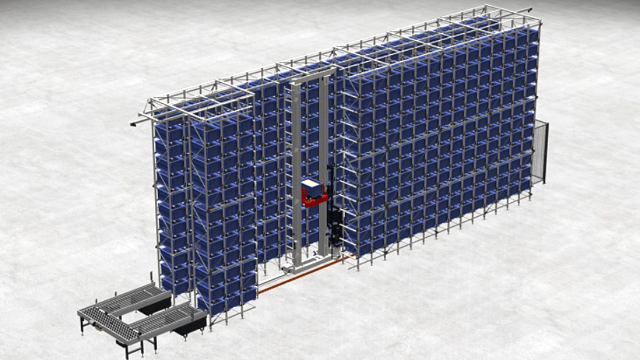

What is Minilaod ASRS system? Miniload ASRS systems are ideal solution to handle light duty loads for various types of plastic cases, plastic containers and boxes, and also provide an extremely high picking system for warehouse racking . miniload system is automated, fast moving and safe operation, and that can be configured according to project requirements.

A miniload system is a high-performance automated warehouse storage system. The stacker crane picks and places the individual loads units ASRS from and into the required items in the shelves.The loads are then taken from the various storage cells and delivered to the output bays, which direct the loading units to another area for picking, packaging or shipment.

Miniload ASRS Features

● Mini load asrs is suitable for goods less than 50KG in weight

● and the application scenarios of multiple varieties products high-density storage.

● The coverage height can be from 5 meters to 12 meters.

● By the material box stacker conveyor sorting system, combined with warehouse stacker, vertical reciprocating conveyor, conveyor sorting systems, WMS, WCS system to complete the goods in and out of storage and sorting function.

Miniload ASRS Application

1.In the warehouse management, Miniload ASRS provide the Storage and buffer for raw materials management, finished goods management, and work in process inventory management

2.Provide the replenishment inventory storage service for warehouse

3.Provide the real-time monitor and security of goods for warehouse

Character of mini load ASRS

Compared with the ASRS System for pallet storage, miniload ASRS is for light duty goods put in the plastic containers, plastic trays, carton boxed and etc.

| Product Name | Warehouse Automated ASRS System |

| Material | Steel Q235,SS400 |

| Loading Capacity | 30KG-300KG |

| Maximum Height | Customized and up to 25,000 mm |

| Rack Depth | Customized |

| Rack Length | Customized |

| Surface Treatment | Powder coated & Galvanized |

| Certificate | CE,ISO,SGS,AS 4084 |

| Usage | Plastic Container, Carton Box |

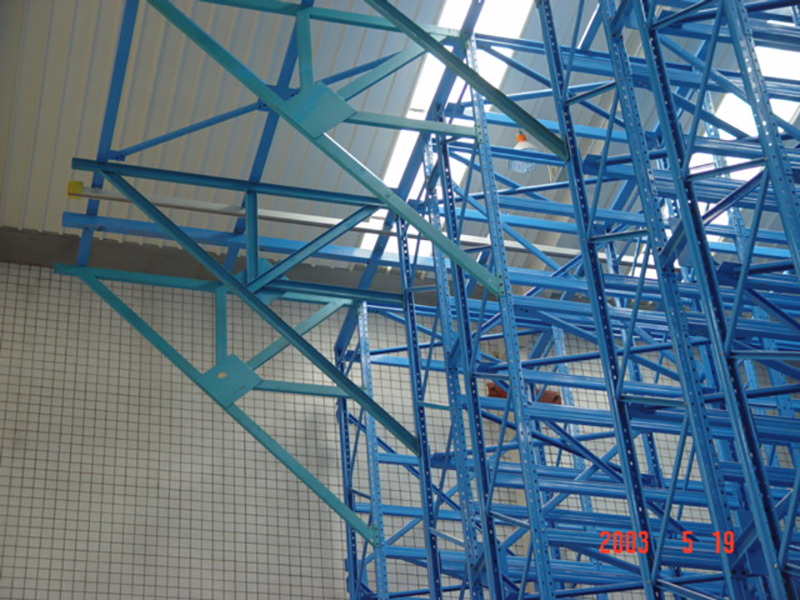

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for OEM manufacturer Conveyor Equipment - Mini load ASRS for Totes and Cartons – Ouman , The product will supply to all over the world, such as: Georgia, Mexico, Turin, Profession, Devoting are always fundamental to our mission. We've got always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.