OEM Factory for Loading Conveyor - Heavy duty electrical movable roll-out cantilever racking – Ouman

OEM Factory for Loading Conveyor - Heavy duty electrical movable roll-out cantilever racking – Ouman Detail:

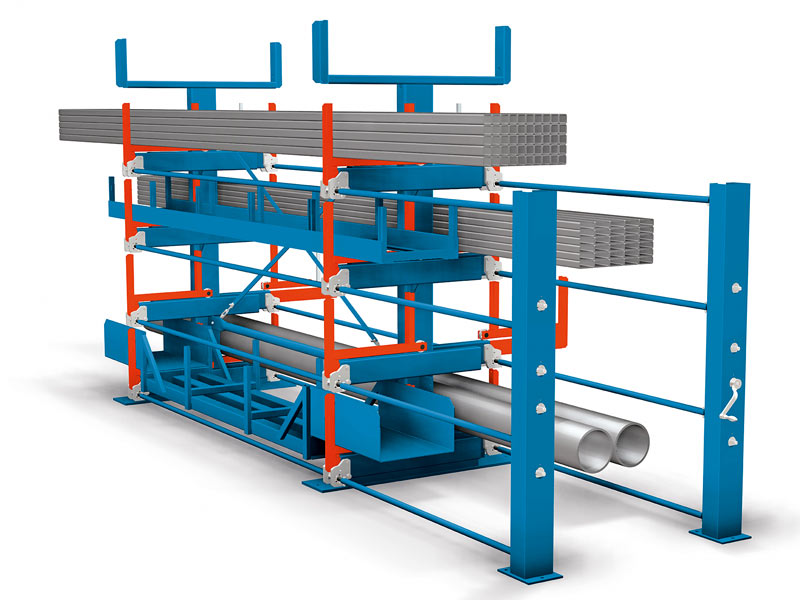

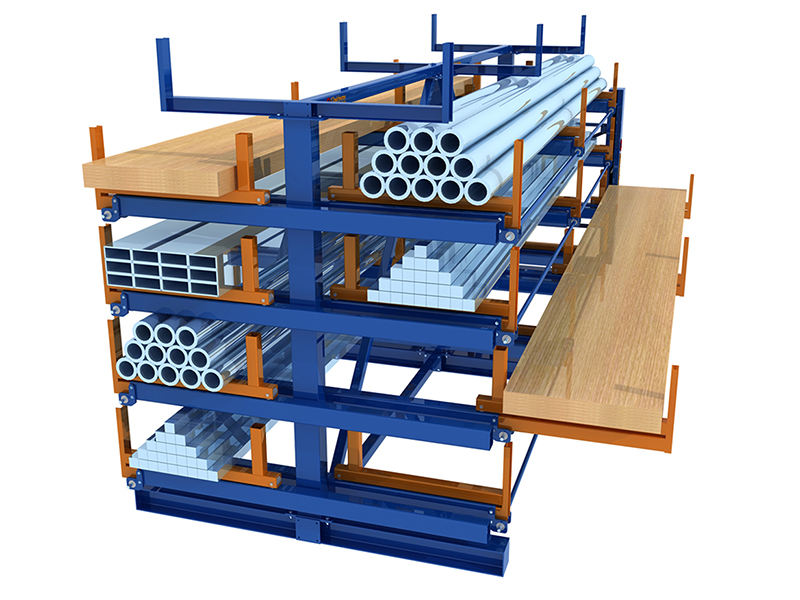

Product Introduction

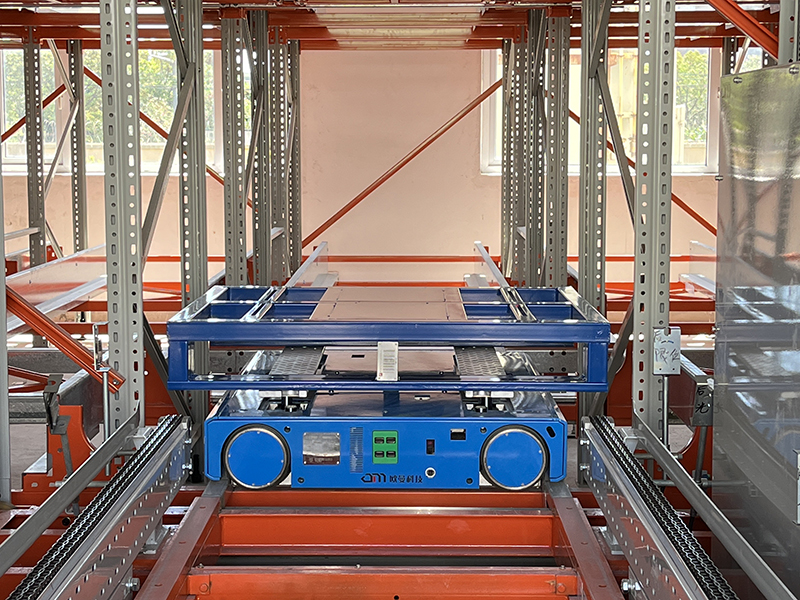

Roll-out Cantilever Racking is an improvement type of traditional cantilever rack.Compared with the standard cantilever rack, the cantilever arms can be retracted, and no need forklifts and wide aisles. With the using the crane to store goods directly, which saves space, especially for companies with limited workshops.

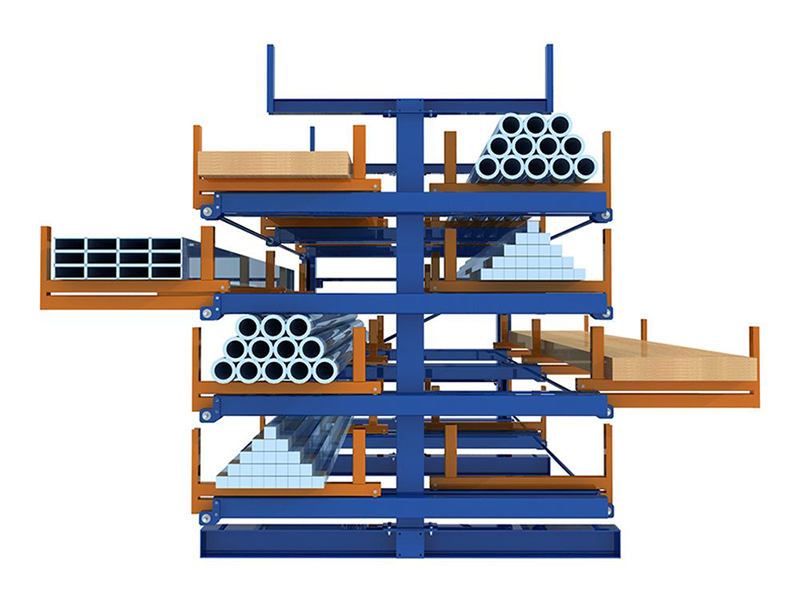

The Roll Out Cantilever Rack can be divided in to double sided and single side two type of cantilever racking. Each cantilever roll-out rack unit is designed with a specific advantage for the end user, whether it be maximum weight capacity, or largest dimension to house long pieces of material.

Technical Data of Cantilever Rack

| Product Name | Roll-out Cantilever Racking |

| Brand Name | OUMAN/ OMRACKING |

| Material | Steel Q235 |

| Size | L4300*W1725*H3615mm and other sizes are also available |

| Levels | Normally 5levels, Base+ Roll-out levels+ Top fixed level |

| Load Capacity | 4000kg max loading |

| Arm Length | Customize size |

| Arm Loading | 500kg-1000kg loading per arm |

| C/C Distance | Customize |

| Certificate | CE,ISO,SGS,AS 4084 |

| Usage | For long shape materials |

Features of Roll-out Cantilever Rack

1.The cantilever is retractable and no need to use forklifts and aisles for forklift operation, which help to save much more space.

2.Roll-out cantilever rack can be used to store pipes, plates, large pieces, shafts, and irregular-shaped goods and long shape material.

3.Max load capacity can reach 4000kg load.

4.Roll out cantilever rack can be designed with single side and double side cantilever rack.

5.Easy to operate and install.

Advantages of the Roll-Out Rack

● Warehouse space is saved and gained

No forklifts are used and small aisles are required and just to use cranes to load and unload the long shape materials

● Racking is much more safe.

The long materials are stored on the beams freely, no need put the materials on the shelving.

● Operation can save much more time.

Without restacking using the hall crane, the racks can be loaded, or transport vehicles can be loaded or unloaded.

● Whole rack structure is easy to operate.

The rack can usually be operated by one person.

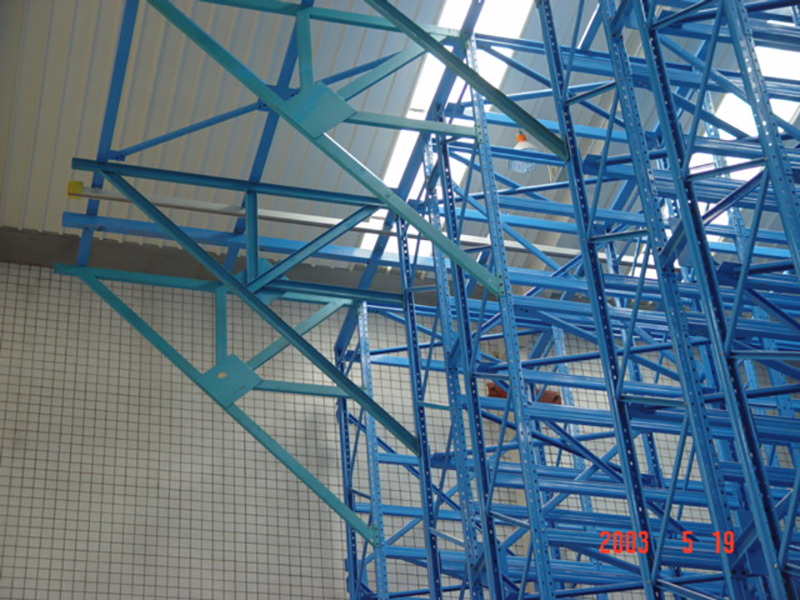

Product detail pictures:

Related Product Guide:

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for OEM Factory for Loading Conveyor - Heavy duty electrical movable roll-out cantilever racking – Ouman , The product will supply to all over the world, such as: Guinea, Australia, Swaziland, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.