OEM Factory for Automated Four Way Shuttle Rack - ASRS with stacker crane & conveyor system for heavy load goods – Ouman

OEM Factory for Automated Four Way Shuttle Rack - ASRS with stacker crane & conveyor system for heavy load goods – Ouman Detail:

Product Introduction

Features of ASRS Shuttle&Convery System

How does ASRS works in the warehouse?

There’re software system and MHE system two part for ASRS.

Software systems including warehouse execution software (WES) and warehouse management software (WMS)

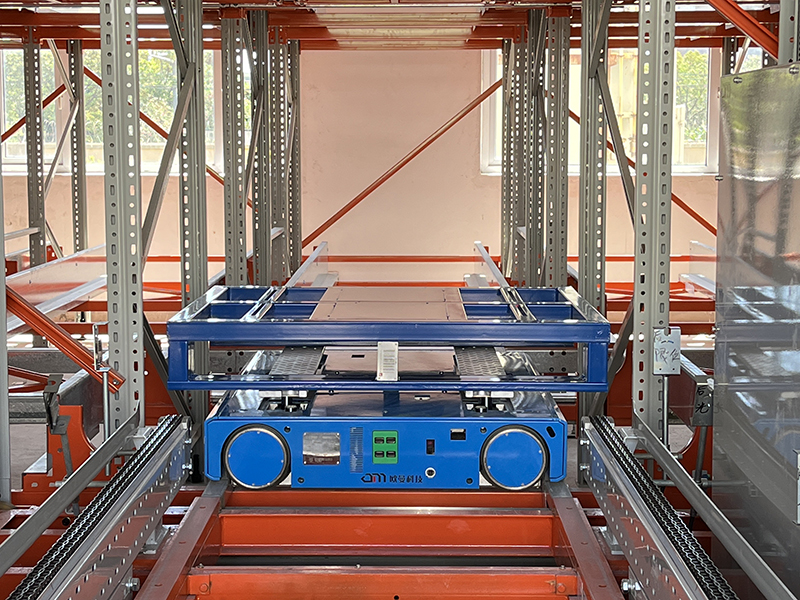

MHE including the stacker cranes, conveyor system , radio shuttles and other equipment.

● WES or WMS give orders to Stacker Cranes and conveyor system to proceed load&unload operation.

● Pallets are picked up from the high bay racking with a stacker crane carriage

● Stacker crane carry the pallets to a system of integrated pallet conveyors to transfer the pallets to internal logistics.

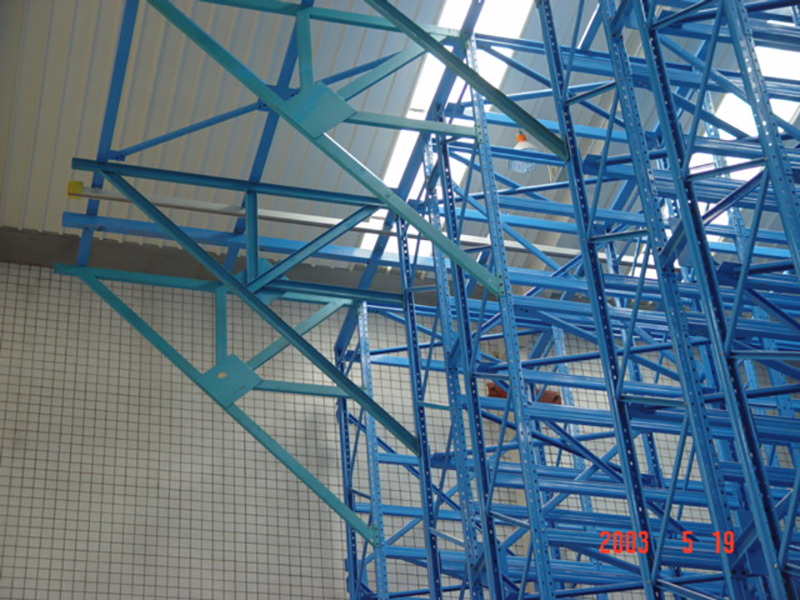

Components of ASRS SYSTEM

Stacker Cranes for ASRS system

Stacker crane is travelling the aisles between racks to load and unload the pallets into the racks and out from the racks.

● Stacker cranes are designed for automated inbound/outbound operations within material storage activities

● The Stacker crane moves lengthwise along the aisles to position or extract pallets. The handling system moves pallets from the picking bays, places them in the storage cells

● Loading units for stacker cranes, all different types of pallets, Containers, Boxes and other types of loading units

Conveyor system for ASRS system

Conveyor systems are usually equipped in the front or back of a warehouse for conveying goods here and there, bridging the procedures done by forklifts and stacker crane by using a roller conveyor or chain conveyor system with lifts, rotating devices and other equipment.

● Conveyor system can be divided into roller conveyor system, chain conveyor system and lift-up transfer conveyor system.

● Conveyor system is powered conveyor system and can work aromatically.

● Different types of conveyor system work together to make the system work efficiency.

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very excellent and aggressive portable digital products for OEM Factory for Automated Four Way Shuttle Rack - ASRS with stacker crane & conveyor system for heavy load goods – Ouman , The product will supply to all over the world, such as: Guatemala, Tunisia, Wellington, Taking the core concept of to be the Responsible. We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!