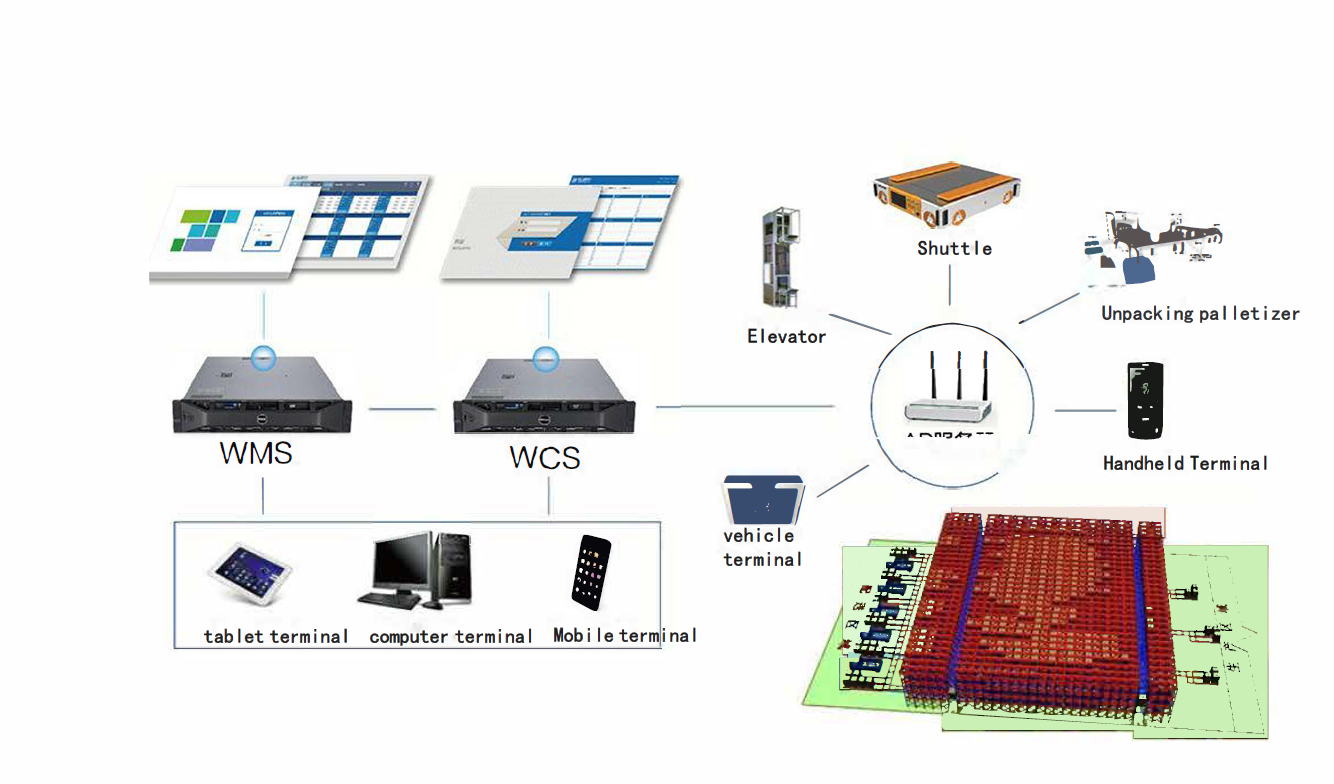

The four-way shuttle rack is a kind of intelligent dense storage rack that has been widely promoted in recent years. By using the four-way shuttle to move the goods on the horizontal and vertical tracks of the rack, a shuttle can complete the handling of the goods. , greatly improving work efficiency. Cooperating with elevators, automated warehouse management system (WMS) and warehouse scheduling system (WCS), the goal of automated warehouse storage can be achieved

The four-way shuttle is not limited by the height of the warehouse, and can make full use of the area, and set different depths according to the number of batches of materials, and invest in batches according to the efficiency requirements of different periods.

The four-way shuttle is developed on the basis of the two-way shuttle, and its biggest advantage is flexibility, which combines the advantages of various current automated logistics equipment. Widely used in medicine, food, tobacco and other industries!

Advantages:

- Super high-rise storage: Improve the overall space utilization rate of the warehouse, save the area occupied by the inventory, and the storage capacity is about 5-6 times that of ordinary warehouses.

- Automatic access: The shuttle car runs and processes quickly, and can transmit the enterprise’s material system and ERP, WMS and other systems in real time.

- Computer control: facilitate the inventory of goods, and reasonably control the range of inventory.

- There are no special requirements on the height, area and irregularities of the warehouseWhen there are too many columns and cannot be arranged in the middle of the shelf, the traditional stacker can only give up the entire space, while the four-way shuttle only needs to avoid the space of the columns.

- The depth of the storage space can be flexibly designed according to the storage capacity of the product SKU.Products of multiple SKUs can be stored in a single aisle depth of the four-way vehicle to utilize the maximum storage space. The traditional stacker vertical warehouse can only be single-deep or double-deep, and the roadway space takes up more space; the four-way shuttle can move the warehouse freely to improve space utilization.

- The number of shuttle cars can be increased according to different efficiency requirements.The four-way shuttle car vertical warehouse can purchase a few units when the efficiency requirements are not high in the early stage, and then purchase a few more units when the warehouse increases. It only needs to be set up to use the system, which is a plug-and-play type.

The 4 way shuttle storage system has many advantages, especially in buildings with many irregular columns, the advantages are more obvious. Of course, as a dense warehouse, the more storage trays a single SKU has, the fewer aisles and the higher the space utilization rate.

Safety Design:

1. Anti-foreign object collision design;

2. Multi-vehicle operation anti-collision design;

3. Laser positioning protection system, no anti-collision signs on the track;

4. Design to reduce vicious work failures:

5. Battery power shortage alarm, when the battery power is low, stop at the entrance and wait for processing;

Applicable occasions:

1. Each lane stores the same type of product;

2. Warehouse where the height of the forklift is limited by the height of the shelf;

3. Warehouses where goods come in and out at both ends or at one end (FIFO or FIFO);

4. Judging from the current logistics and warehousing model, it is widely used in medicine, food, tobacco and other industries;

Post time: Jul-07-2023