New Fashion Design for Warehouse Management - Automated multi layer ACR for warehouse storage – Ouman

New Fashion Design for Warehouse Management - Automated multi layer ACR for warehouse storage – Ouman Detail:

Product Introduction

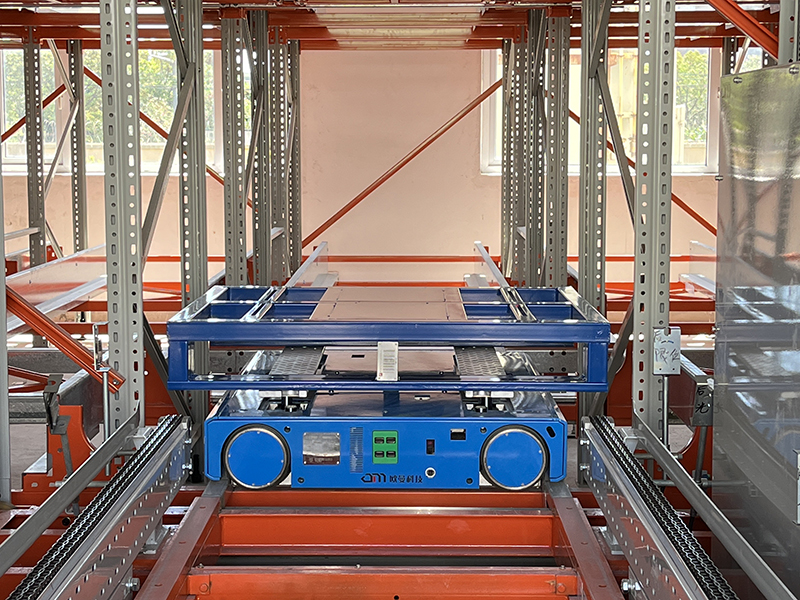

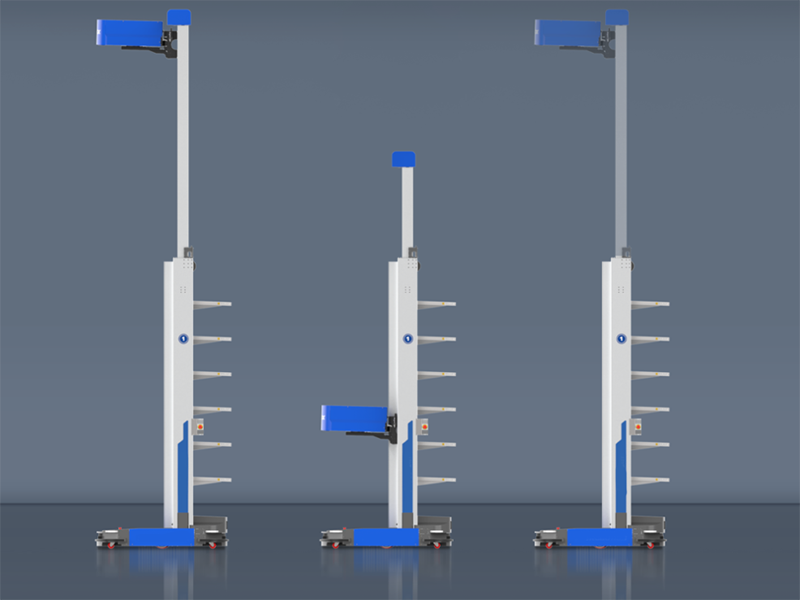

ACR is the short of Autonomous Case-handling Robots, which is automated robots to carry the plastic toes or plastic containers to achieve the goods-to-person (G2P) automation model in a warehouse. In the system, the Robots walking in the warehouse with following the QR code navigation.

ACR system includes the ACR, intelligent charging pillar, racking shelving, multi function working station , WMS, WCS and relative internet hardware system.

Technical Data of Double Deep ACR

|

Item Name |

Multi Layer ACR |

|

Brand Name |

Ouman/ OMRACKING |

|

Lifting Height |

Max Height 5200mm |

|

Walking Speed |

Avg: 1.5m/s , Max:1.8m/s |

|

Plastic Container Nos |

Normally 5pcs, but can do with 8+1 pcs |

|

Plastic Container Size |

600x400x120-300mm / customize size |

|

Container Load |

30kg-50kg |

|

Navigation Methods |

Inertial navigation+ DM Code |

|

Battery life |

More than 5.4h |

|

Racking Type |

Medium duty Racking Shelving |

|

Aisle Width |

1110mm |

|

Ground Flatness |

± 4mm/m2 |

Advantage of Multi layer ACR

1)High Working efficiency:

Max plastic cases of our multi layers ACR carry is 8+1 pcs, this can help improve the working picking efficiency greatly.

2)Flexible payload dimensions:

Our automated picking robots supports separate and mixed picking of plastic totes and carton boxes. So it can support many different dimensions and types of cases.

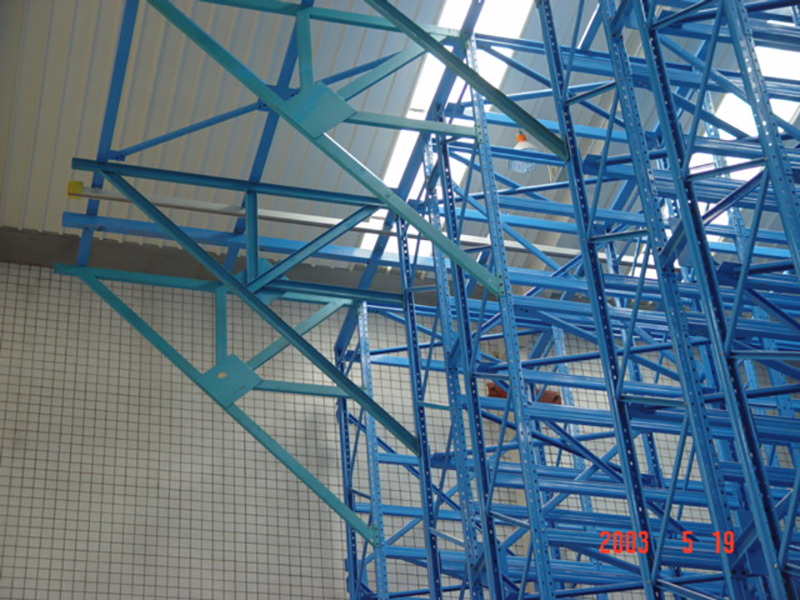

3)Strong flexible with racking solution

If new warehouse,we can design with more rows racking shelving but if existing racking, we can provide renovation plan based on the old racking to achieve the function high storage density.

4)High safety

The automated picking robots have the safety device to make sure it works in safe condition.

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers. New Fashion Design for Warehouse Management - Automated multi layer ACR for warehouse storage – Ouman , The product will supply to all over the world, such as: Estonia, Birmingham, venezuela, We aim to become the modern enterprise with the commercial ideal of Sincerity and confidence and with the aim of Offering customers sincere services and high quality products. We sincerely ask for your unchanged support and appreciate your kind advice and guidance.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a excellent partner!