factory Outlets for Asrs Stacker Crane - Automatic Heavy duty commercial storage industrial 4way automated shuttle racking – Ouman

factory Outlets for Asrs Stacker Crane - Automatic Heavy duty commercial storage industrial 4way automated shuttle racking – Ouman Detail:

Product Introduction

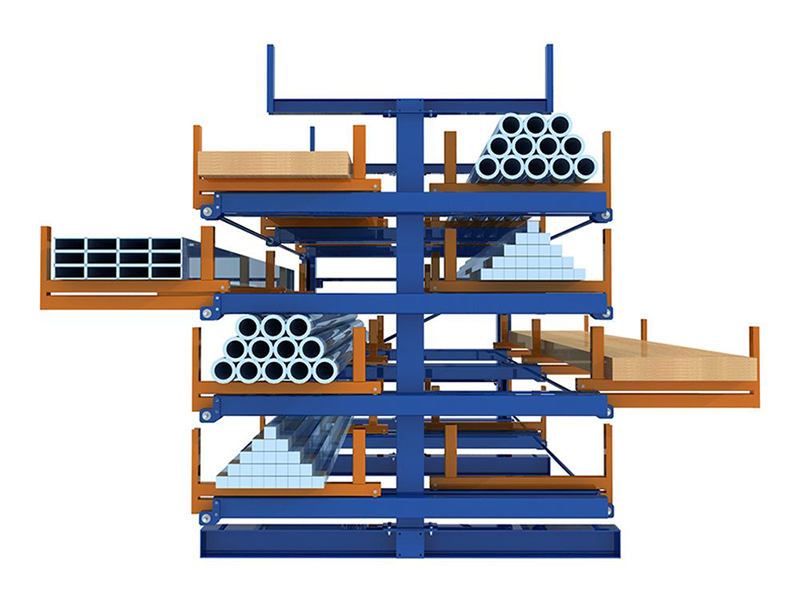

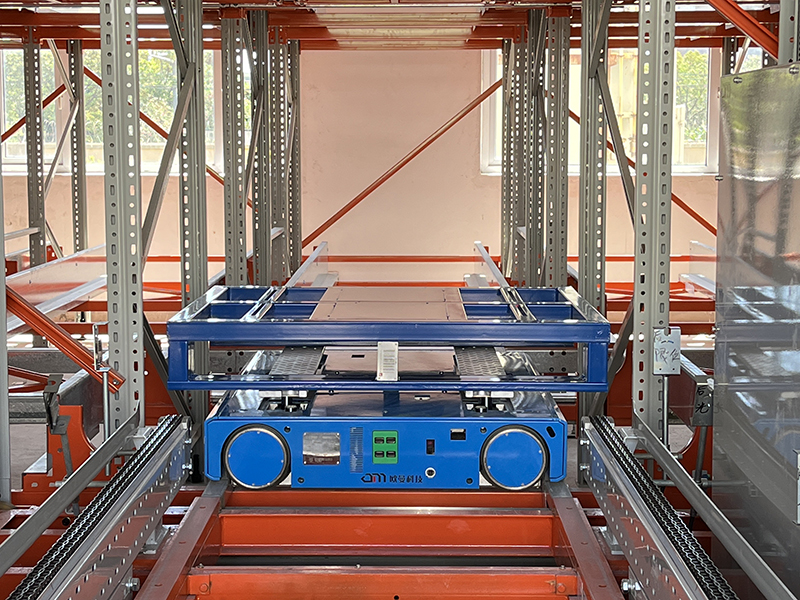

Automatic Heavy duty commercial storage industrial 4way automated shuttle racking, and this is for the storage and retrieval system for palletized goods. It’s an ideal solution for the storage of goods with mass quantity but small SKU, widely used in the industry of Food&beverage, chemical, third party logistics etc. It’s an updated version of standard radio shuttle system. The shuttle is able to move in 4 directions on the storage lanes and main lanes.

Featured Advantage

1.The system is easy to use since four way shuttle rack used together with wcs & wms

2.Save more much time and money

3.Provide the high storage density for warehouse storage

4.WCS dispatches vehicle operations, real-time monitoring of vehicle coordinate position, speed, power and other status

Technical Data of Four Way Shuttle Racking

Standard 4way automated shuttle cart

|

Loading |

Work Speed |

Pallet Size |

Temperature |

Battery |

Battery Type |

Weight |

|

Max 1500kg |

1.0m/s |

W1200-1600 D800-1200 |

Normal Temperature |

48V/40AH |

Lithium Iron Phosphate |

450KG |

|

Max 1200kg |

1.2m/s |

Vertical Lift for 4way shuttle racking

|

Loading |

Lift Speed |

Size |

Temperature |

|

2500kg max loading |

0.9m/s |

Customize |

-25°C-45°C |

|

Lift Up Information |

Speed/Acceleration | 0.9m/s Max | 0.3m/s2 |

| Motor Information | Panasonic | Servo Control | |

| Control Method | Manual Operate/Stand-alone automatic/Automatic | ||

|

Positioning Method |

Encoder |

± 2mm |

|

| Detection Sensor |

Photoelectric Sensors |

||

| Location Limit |

Position Switch |

||

|

Control Method |

Panasonic PLC control |

||

|

Communication Method |

MODBUS-TCP |

||

|

Power Supply Method |

Power cable,AC380V,50Hz |

||

|

Working Noisy |

≤70db |

||

|

Temperature |

-18°C |

||

Conveyor System

The conveyor system of four way shuttle racking including the chain conveyor system, roller conveyor system and Lift-up Transfer Machine. The function of conveyor system is to drive the motors of conveyor system clockwise running,reversed running, lifting up, and 90 degree steering. This function is to deliver the goods on the conveyor line and transfer to travel on other equipment.

Warehouse Control System( WCS)

① System Management

② Task Management

③ Device Management (Shuttle carts, vertical lifts,charging,Error information and working data)

④ Job Scheduling

⑤ Real Time Monitoring

⑥ Basic Data

Warehouse Management System (WMS)

System Permit

Configuration Information

Count Management

Management System

Inbound Management

Shift Management

Basic Information

Outbound Management

Inventory Management

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers. factory Outlets for Asrs Stacker Crane - Automatic Heavy duty commercial storage industrial 4way automated shuttle racking – Ouman , The product will supply to all over the world, such as: America, Barcelona, Germany, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.