Factory making Automated Case-Handling Robots - Four way radio shuttle racking for asrs warehouse storage racking system – Ouman

Factory making Automated Case-Handling Robots - Four way radio shuttle racking for asrs warehouse storage racking system – Ouman Detail:

Comparison of four way shuttle racking & ASRS

|

Item Comparison |

ASRS |

4way shuttle racking system |

|

Suitable warehouse |

20m length at least |

High,low and old warehouse |

|

Flexible Layout |

Single/double deep |

Add radio shuttles |

|

Failure Loss |

Crane broken, whole aisle stops |

Shuttle error,other shuttles work |

|

Storage Utilization |

Low storage utilization |

High storage utilization |

|

Invest cost |

High cost |

Low cost |

|

Energy consumption |

High |

Low |

|

Working limit |

Stacker crane only work one aisle |

Shuttle can work all pallet postion |

|

Working model |

FIFO&FILO |

FIFO&FILO |

|

Maintain cost |

High |

Low |

|

Shift |

Shift with conveyor system |

Shift easily |

Comparison of four way shuttle racking & standard pallet racking

|

Item Comparison |

SPR |

4way shuttle rack |

|

Warehouse type |

Normal warehouse, forklift use |

High automatic warehouse |

|

Storage utilization |

Low |

High |

|

Working Efficiency |

25pallets/hours |

25pallets/hours but add shuttles |

|

Warehouse operation |

Manual operation |

Automatic operation |

|

System reliability |

Manual operation, not very reliable |

Multi shuttles work together,reliable |

Required information

1.Pallet size: Length, width, height

2.Pallet type: plastic pallet, wooden pallet or steel pallet

3.Warehouse working time: how many hours for warehouse works

4.Inbound warehouse working efficiency

5.Outbound warehouse working efficiency

6.Working models: FIFO or FILO

7.Required storage pallet positions

8.Warehouse size: length, width and height

9.Cargo size and weight

10.Cargo type on pallet: any multi kinds of cargoes on the pallet

11.SKU quantity

12.Single SKU quantity

13.Distribution area set in the warehouse or not

14.Load&unload models for cargoes

Project case

Garment Industry

The warehouse located in the east of China. The main products are garment materials.

Basic information of warehouse & product

1)Warehouse size L57000mm*W48000mm*H10000mm

2)Cargo with pallet size: L1200*D1000*H1500mm

3)Cargo with pallet weight: 1000kg/pallet

4)Working efficiency: 160Pallets/Hour

Designed drawing

1.Storage pallet position: 5584 Pallet Positions

2.Pallet positions for AGV forklift: 1167 Pallet Positions

3.Vertical forklift quantity: 4pcs

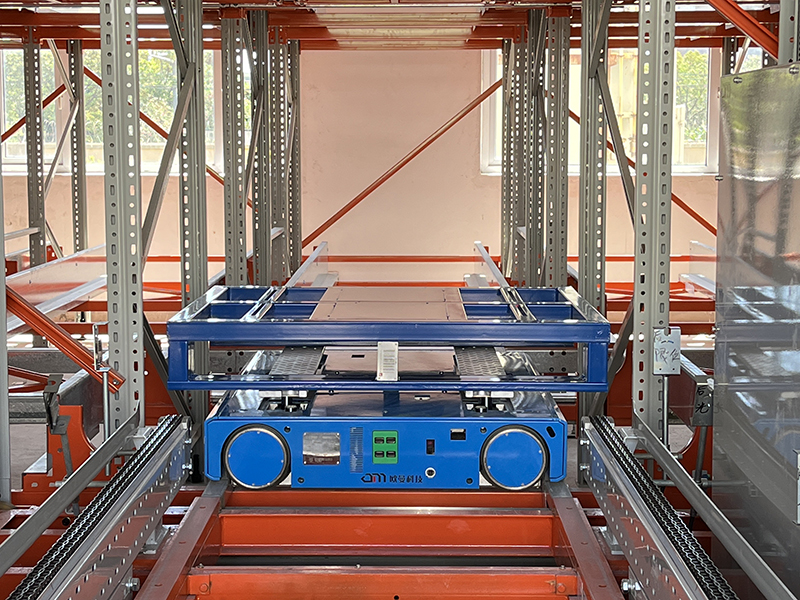

4.Four way shuttle carts: 5 radio shuttle carts

5.AGV forklifts used together with conveyor system and racking system.

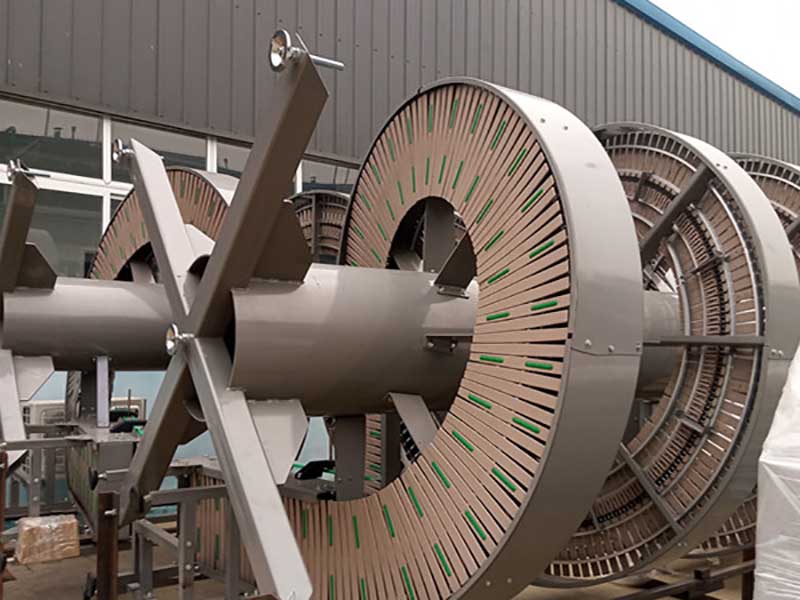

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Factory making Automated Case-Handling Robots - Four way radio shuttle racking for asrs warehouse storage racking system – Ouman , The product will supply to all over the world, such as: Comoros, Jeddah, European, We have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!