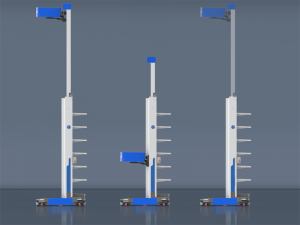

Double deep automatic picking robots for racking shelving

Product Introduction

Double deep automatic picking robots for racking shelving is similar with multi layer automated ACR. But the most difference is the fork of robot can work ask VNA forklift fork to pick out of put in the left side case after complete the load and unload for right side.

In the most projects, normally we combine the multi-layer automated ACR together with double deep ACR, because the double deep ACR can owns the function of Multi-layers. The max qty of cases which ACR can carry is also 9pcs.

Technical Data of Double Deep ACR

|

Item Name |

Double Deep ACR |

|

Brand Name |

Ouman/ OMRACKING |

|

Lifting Height |

Standard height is 4200mm but 1000-5000mm is available |

|

Walking Speed |

Min 1.5m/s max 1.7m/s |

|

Case Nos |

9pcs |

|

Plastic Container Size |

600x400x120-300mm / customize size |

|

Container Load |

30kg-50kg |

|

Navigation Methods |

Inertial navigation+ DM Code |

|

Battery life |

More than 5.4h |

|

Racking Type |

Medium duty Racking Shelving |

|

Aisle Width |

1110mm |

|

Ground Flatness |

± 4mm/m2 |

|

Types of cases |

Plastic contanier,Plastic Tray, Carton Box |

|

Flexible |

Different type cases can use together and different size of case can use together, the cases can be used more than one time |

|

Color |

Racking color can be customized |

|

Certificate |

CE, ISO9001, |

Advantage of Double Deep ACR

1.To achieve automated picking, handling, navigation and charing full automatic working for warehouse

2. the max height can be with about 5m and multi layer cases and can do with 9cs cases.

3. Obstacle detection, active obstacle avoidance, anti-collision alarm, and emergency stop.

4,Automated picking robot can support with cartons/totes, multi-size cases.

5. Supports different customized requirements including height and color