Best-Selling Mobile Gravity Flow Rack - ASRS with stacker crane & conveyor system for heavy load goods – Ouman

Best-Selling Mobile Gravity Flow Rack - ASRS with stacker crane & conveyor system for heavy load goods – Ouman Detail:

Product Introduction

Features of ASRS Shuttle&Convery System

How does ASRS works in the warehouse?

There’re software system and MHE system two part for ASRS.

Software systems including warehouse execution software (WES) and warehouse management software (WMS)

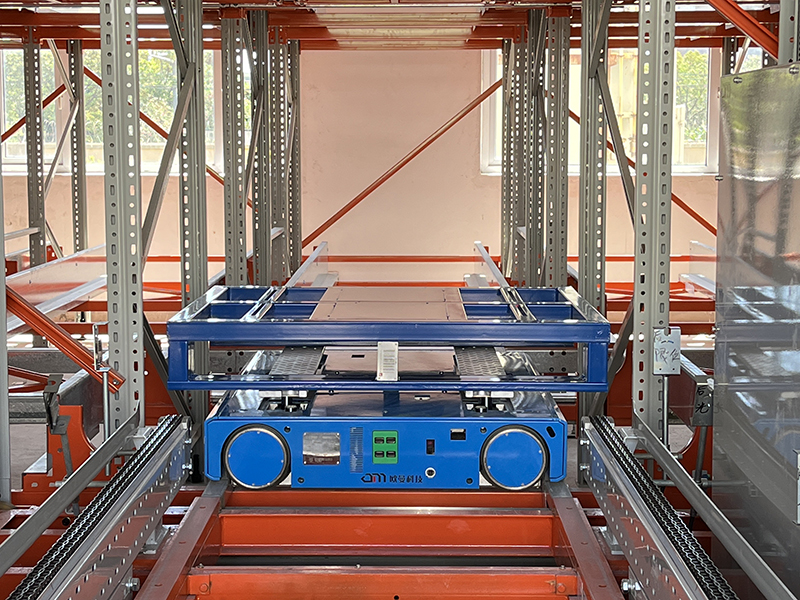

MHE including the stacker cranes, conveyor system , radio shuttles and other equipment.

● WES or WMS give orders to Stacker Cranes and conveyor system to proceed load&unload operation.

● Pallets are picked up from the high bay racking with a stacker crane carriage

● Stacker crane carry the pallets to a system of integrated pallet conveyors to transfer the pallets to internal logistics.

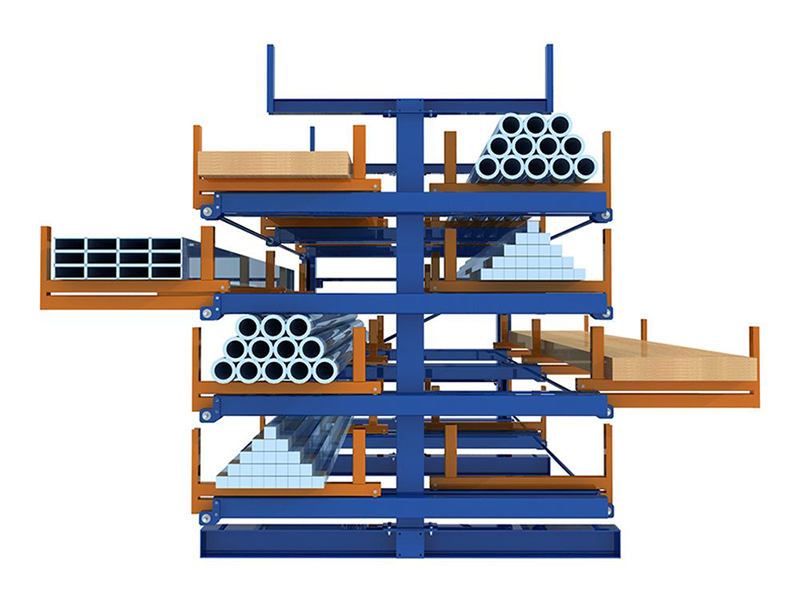

Components of ASRS SYSTEM

Stacker Cranes for ASRS system

Stacker crane is travelling the aisles between racks to load and unload the pallets into the racks and out from the racks.

● Stacker cranes are designed for automated inbound/outbound operations within material storage activities

● The Stacker crane moves lengthwise along the aisles to position or extract pallets. The handling system moves pallets from the picking bays, places them in the storage cells

● Loading units for stacker cranes, all different types of pallets, Containers, Boxes and other types of loading units

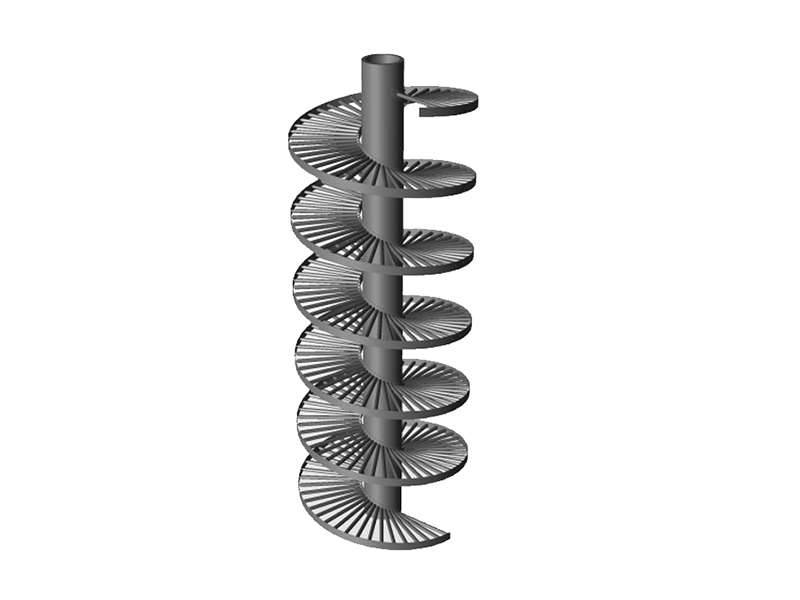

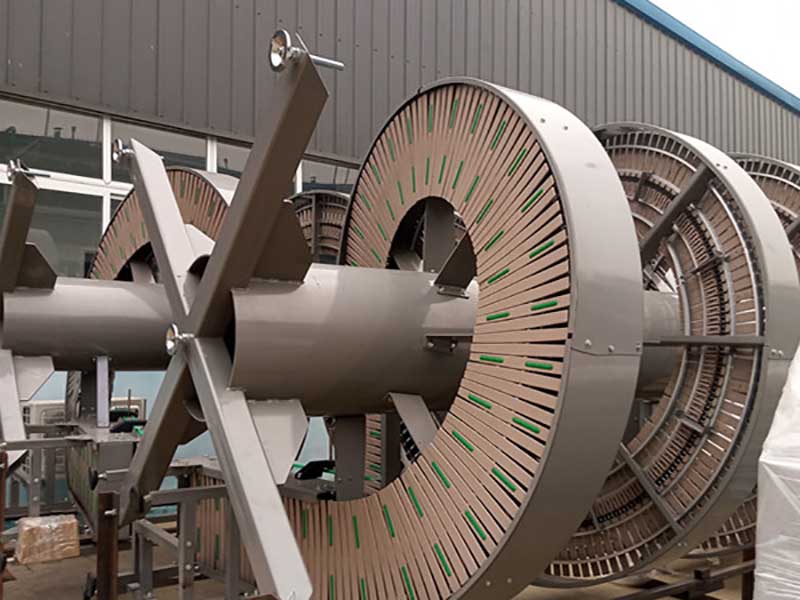

Conveyor system for ASRS system

Conveyor systems are usually equipped in the front or back of a warehouse for conveying goods here and there, bridging the procedures done by forklifts and stacker crane by using a roller conveyor or chain conveyor system with lifts, rotating devices and other equipment.

● Conveyor system can be divided into roller conveyor system, chain conveyor system and lift-up transfer conveyor system.

● Conveyor system is powered conveyor system and can work aromatically.

● Different types of conveyor system work together to make the system work efficiency.

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our great general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for Best-Selling Mobile Gravity Flow Rack - ASRS with stacker crane & conveyor system for heavy load goods – Ouman , The product will supply to all over the world, such as: Australia, Myanmar, Seychelles, We welcome customers from all over the world come to discuss business. We supply high quality solutions, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.