Best Price on Heavy Duty Cantilever Racks - Automatic 4way shuttle racking for warehouse storage – Ouman

Best Price on Heavy Duty Cantilever Racks - Automatic 4way shuttle racking for warehouse storage – Ouman Detail:

Product Introduction

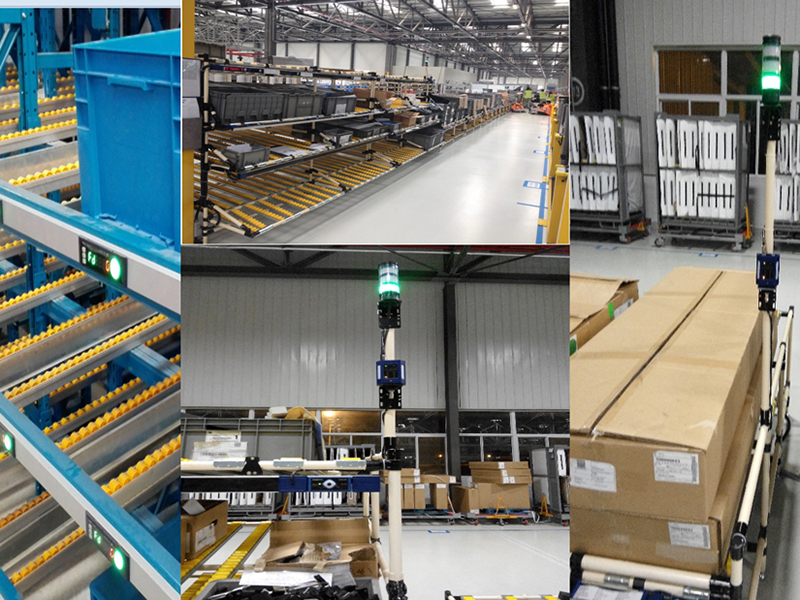

Automatic 4way shuttle racking for warehouse storage is an intelligent storage and handling system that all directions travels on the guide rails , shifts the vertical levels, automatic storage load&unload, intelligent control system, dynamic management,obstacle perception. The four way shuttle can be applied with vertical lifts, conveyor system for inbound&outbound service, racking system ,warehouse management system and warehouse control system, which realized the automatic storage and handling.

Automatic 4way shuttle racking supports FIFO,FILO,single-channel multi-SKU storage and pick up and all inbound and outbound models.

Advantages of automatic four way shuttle racking system

1.Automatic 4way shuttle rack system greatly increase the storage capacity that is about 3-4 times more than normal storage racking system

2.Economic ,time saving automatic racking system improve the storage capacity and reduce the labor cost

3.Four way shuttle is a type fully automatic racking system and reduce the risk damage compared with traditional racking system.

4.If need to adjust the storage capacity and inbound&outbound working efficiency, this system just need to reduce or add the quantity of four way shuttle carts.

5.Automatic four way shuttle rack owns the WMS, WCS system to integrate the existing warehouse upper systems to archive the fully automatic warehouse racking solution.

Components of automatic four way shuttle racking

Warehouse racking system

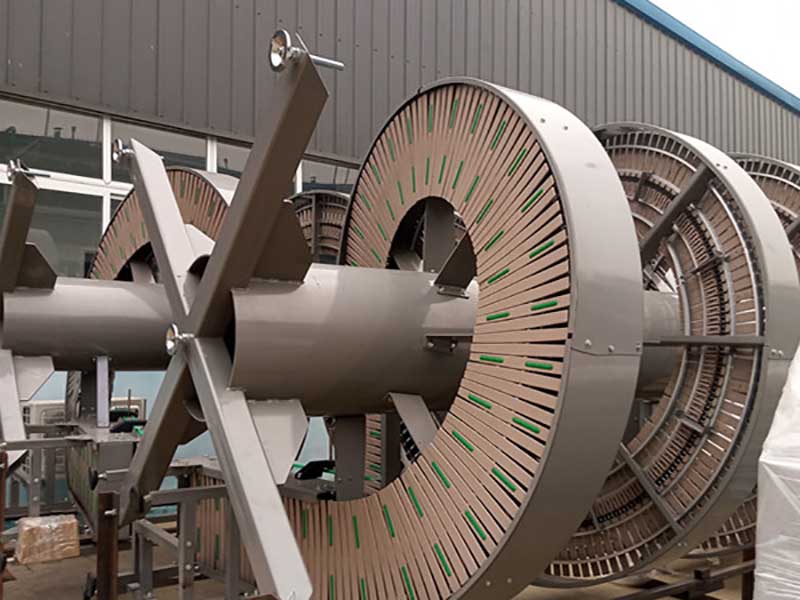

Automatic four way shuttle cart

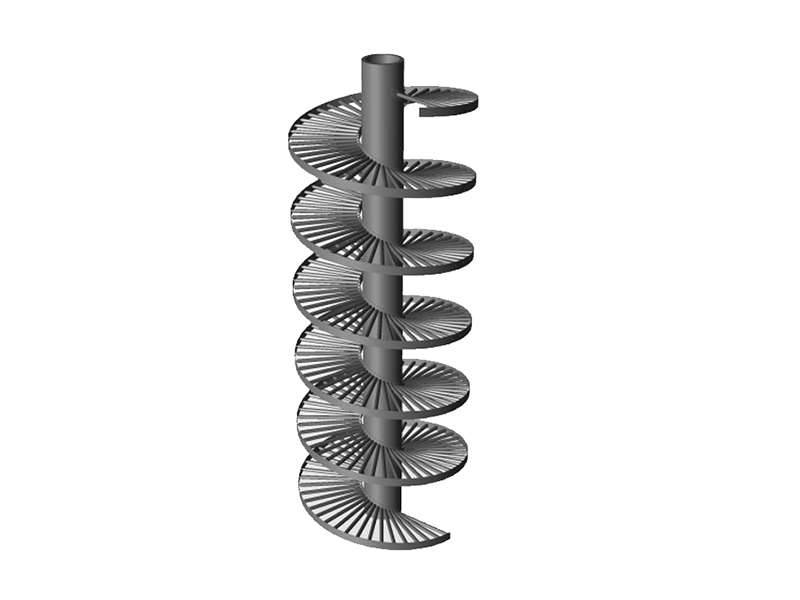

Vertical lift to shift the layers

Conveyor system: Roller conveyor system, Chain conveyor system, lift-up transfer machine

Automatic charging device

Out-shape detecting device

Weight equipment

Fixed scanner

Warehouse Management System

Warehouse Control System

Related internet and electrical control system

Related Equipment for four way shuttle rack

Product detail pictures:

Related Product Guide:

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the great support for Best Price on Heavy Duty Cantilever Racks - Automatic 4way shuttle racking for warehouse storage – Ouman , The product will supply to all over the world, such as: Jakarta, Buenos Aires, Greece, Our product quality is one of the major concerns and has been produced to meet the customer's standards. Customer services and relationship is another important area which we understand good communication and relationships with our customers is significant power to run it as a long term business.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a nice choice.