Autonomous Case-handling Robots (ACR)

-

Revolutionize Your Warehouse with OUMAN RACKING ACR

OUMAN RACKING’s Multi-Layer Automated Case-Handling Robot (ACR) is a state-of-the-art solution designed to streamline warehouse operations. By leveraging advanced autonomous navigation technology, the ACR system implements a Goods-to-Person (G2P) automation model, significantly enhancing efficiency and accuracy.

-

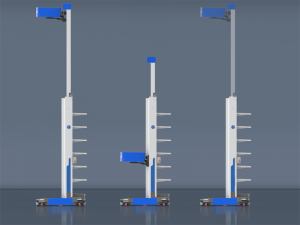

Double deep automatic picking robots for racking shelving

Double deep automatic picking robots for racking shelving is similar with multi layer automated ACR. But the most difference is the fork of robot can work ask VNA forklift fork to pick out of put in the left side case after complete the load and unload for right side.

-

Automated multi layer ACR for warehouse storage

ACR is the short of Autonomous Case-handling Robots, which is automated robots to carry the plastic toes or plastic containers to achieve the goods-to-person (G2P) automation model in a warehouse. In the system, the Robots walking in the warehouse with following the QR code navigation.

ACR system includes the ACR, intelligent charging pillar, racking shelving, multi function working station , WMS, WCS and relative internet hardware system.