Automatic racking system with radio shuttle system

Product Introduction

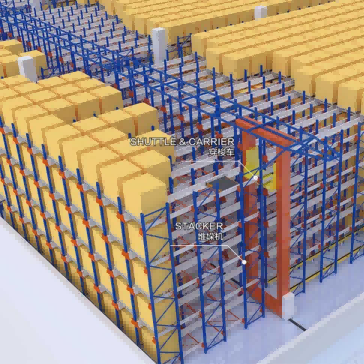

Asrs with radio shuttle system is another types of full automatic racking system. It can store more pallet positions for the warehouse. The system is composed of stacker crane, shuttle, horizontal conveying system, racking system, WMS/WCS management control system. The stacker replaces the shuttle carrier and the vertical hoist, which simplifies the horizontal and vertical handling processes. It is the integration of the traditional crane stacker and shuttle technology to achieve high dense storage.

Features of ASRS shuttle racking system

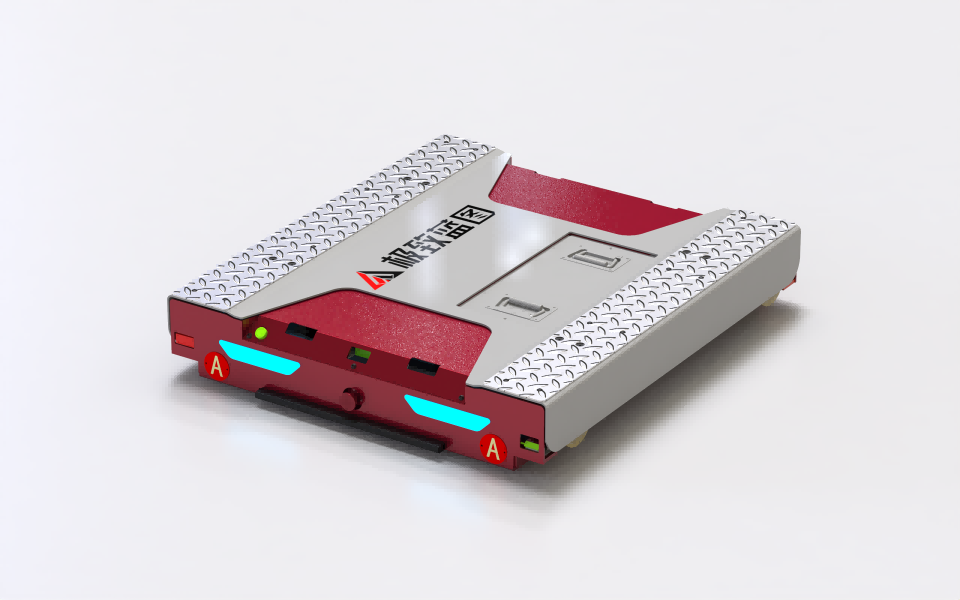

1.In the ASRS shuttle racking system, Stacking crane is the main equipment in automated storage system. It can walk along the horizontal and vertical direction according to the computer instructions between the aisles to realize the function of aisle changes. The radio shuttle can instead of the stacker fork to achieve the function of accessing goods.

2.Storage density is much higher than normal warehouse storage and stacker can be used together with multi shuttles to work together.

3.ASRS with shuttle system is used normally for high storage density demand but not high working efficiency warehouse requirement

4.Increasing the depth and height of racks, and nos of pallet runners and reducing the stacker cranes to reduce the cost.

5.ASRS provide the low cost of comprehensive investment for automatic racking system

Stacker Crane Specification

|

Type |

Light Duty Stacker Crane |

Mid Duty Stacker Crane |

Heavy Duty Stacker Crane |

|

Load Capacity |

20-200kg |

250-1500kg |

≥ 2000kg |

|

Rack Height(m) |

≤ 25meters |

||

|

Cargo Size |

1200*1000/1200mm |

||

|

Fork type |

Single /Double/Multi fork |

||

|

Running Speed(m/min) |

0-240 |

0-180 |

0-180 |

|

Lift Speed(m/min) |

0-60 |

0-50 |

0-40 |

|

Fork telescopic Speed(m/min) |

Full load:0-30 Unload:40 |

Full-load:0-20 Unload: |

|

|

Communication Method |

Infrared&Wireless Communication |

||