Automated warehouse storage satellite shuttle racking

Product Introduction

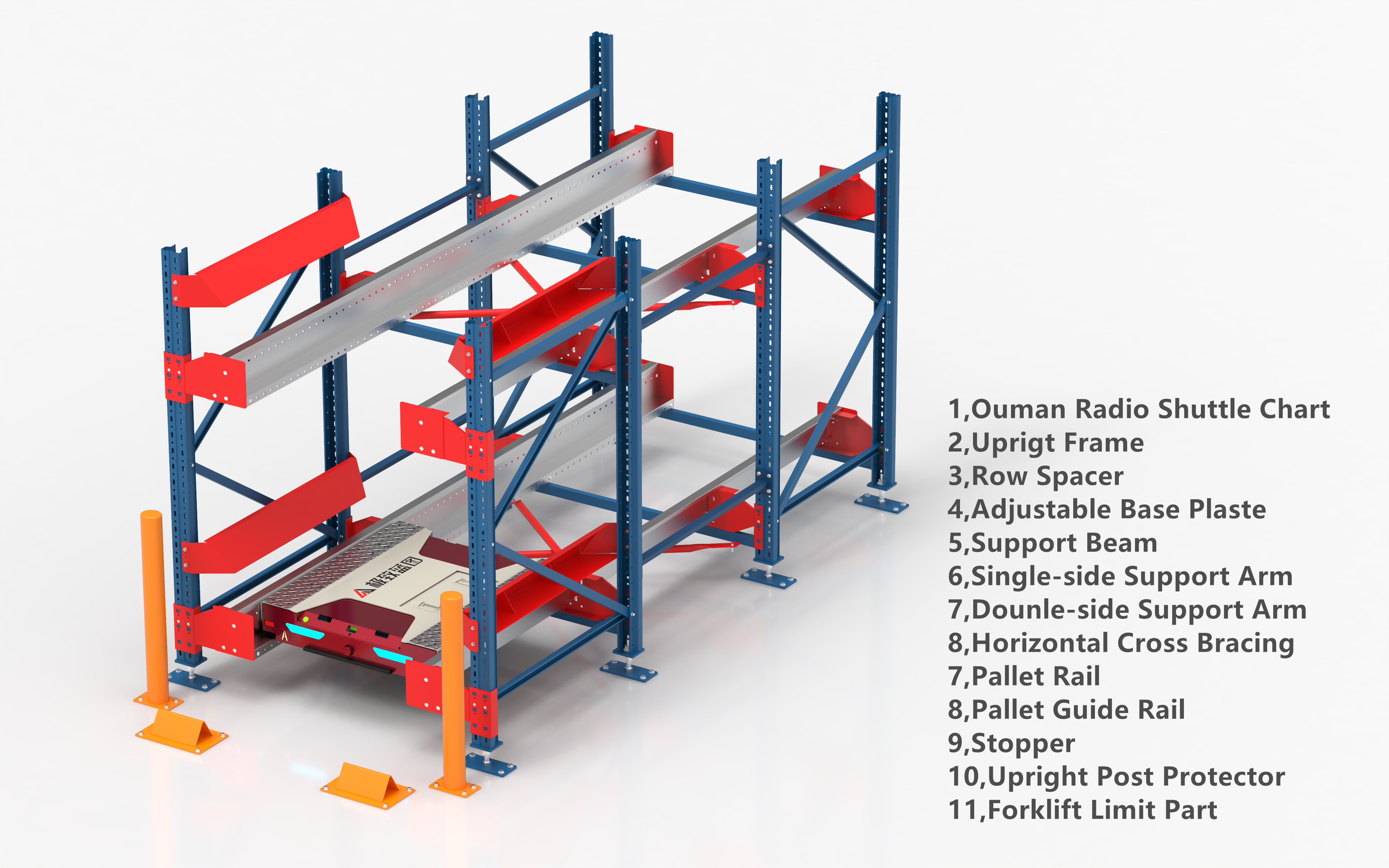

High Space Utilization Heavy Duty satellite Radio Shuttle Racks is is a high-density automatic storage racking system. Radio shuttle racking consists of shuttle racking part, shuttle cart, forklifts.

And it improve the warehouse storage utilization and high working efficiency, which reduce the many labor works.Forklifts no need to drive in the racking, so shuttle racking work with safety with no collision of racking. Normally radio shuttle racking solution is suitable for food, beverage, chemical, tobacco and other single variety, large batch, product relatively single industry.

Basic Information of shuttle racking

|

Product Name |

Radio Shuttle Rack |

|

Brand Name |

Ouman Brand/OMRACKING |

|

Material |

Q235B/Q355 Steel(cold storage) |

|

Color |

Blue, Orange,Yellow,Gray,Black and customize color |

|

Loading&Unloading |

First in Last Out, First in First Out |

|

Max loading |

1500kg loading |

|

Operation Model |

Manual Operation & Automatic Operation |

|

Temperature |

Normal Standard Warehouse & Cold Storage Warehouse |

|

Components |

Racking, Pallet Rail, Support Arm, Bracing, Post Protectors, Shuttle Carts |

|

Package |

Standard Package for Export |

|

Manufacture Capacity |

3000kg per month |

|

Payment Terms |

30%TT,70% Balance payment against BL Copy; 100% LC at sight |

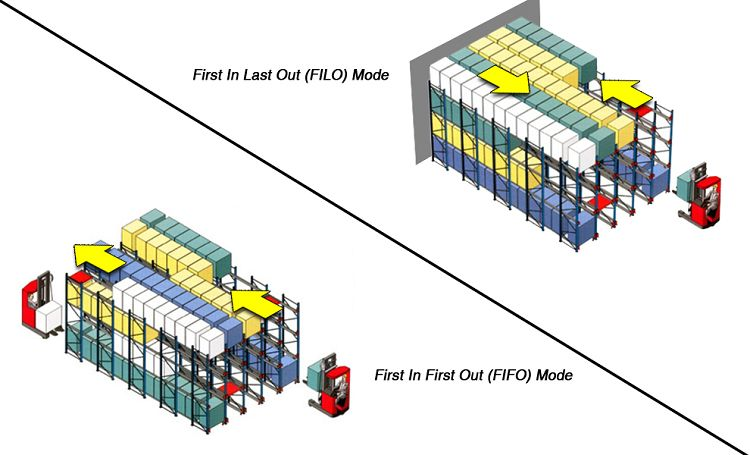

FIFO&FILO Warehouse Management Models

The use of automated shuttles in place of forklifts during the storage process not only reduces the risk of accidents, but also the maintenance costs resulting from damage of the rack.

This system can work either as FIFO or as LIFO, even in freezer chambers, with temperatures of up to -30°C.

FIFO- First in First Out. FIFO management system allows the first placed inventory to be moved first.

FILO-First in Last Out. FILO management system allows the last placed inventory to be moved first.

Function of Shuttle Cart

Ouman Shuttle Cart is an automated logistic equipment for automatic racking system and shuttle cart have many functions to achieve the warehouse management.

|

Shuttle Cart |

Inbound-load the goods into the racking system |

| Outbound-unload the goods from racking system | |

| Inbound Continuously-load goods into rack continuously | |

| Outbound Continuously-unload goods from rack continuously | |

| Transfer-transfer goods from original pallet position to another pallet position | |

| FIFO & FILO- First Pallets in, First Pallets out; First Pallets in, Last Pallets out | |

| Inventory - check the pallet nos of load&unload, transfer and balance pallets |

FAQ

1. Q: What is the max capacity of this radio shuttle rack system?

A: Regular weight per pallet range from 200kg to 1500kg max capacity can reach 2000kg per pallet (customized)

2. Q: What is the max length of the racking lane?

A: Max 100m, within remote controller range.

3. Q: Is it ok in cold room?

A: Yes, max can do -25℃ warehouse.

4. Q: How long is the shuttle car battery life?

A: This battery can charge 1000 times, usually we suggest equip a spare battery.

5. Q: How long working time for once battery charge?

A: 3 hours charge time can work 8 hours continuously.